In the world of industrial manufacturing, precision and efficiency are non-negotiable. Traditional welding methods often fall short when it comes to delivering flawless, high-speed results. That’s where laser beam welding tool technology steps in—revolutionizing the way industries join metals with unmatched accuracy. At LaserChina, we specialize in cutting-edge laser welding solutions designed to enhance productivity, reduce waste, and deliver superior weld quality.

Why Choose Laser Beam Welding?

Laser beam welding is a game-changer for industries requiring high precision, such as automotive, aerospace, electronics, and medical device manufacturing. Unlike conventional welding techniques, laser welding uses a concentrated beam of light to fuse materials with minimal heat distortion. This results in:

Higher Precision: The focused laser beam allows for micro-welding with pinpoint accuracy.

Stronger Joints: Produces deep, narrow welds with superior mechanical properties.

Faster Speeds: Significantly reduces production time compared to TIG or MIG welding.

Minimal Material Waste: Reduced heat-affected zones mean less warping and cleaner finishes.

LaserChina’s Advanced Welding Solutions

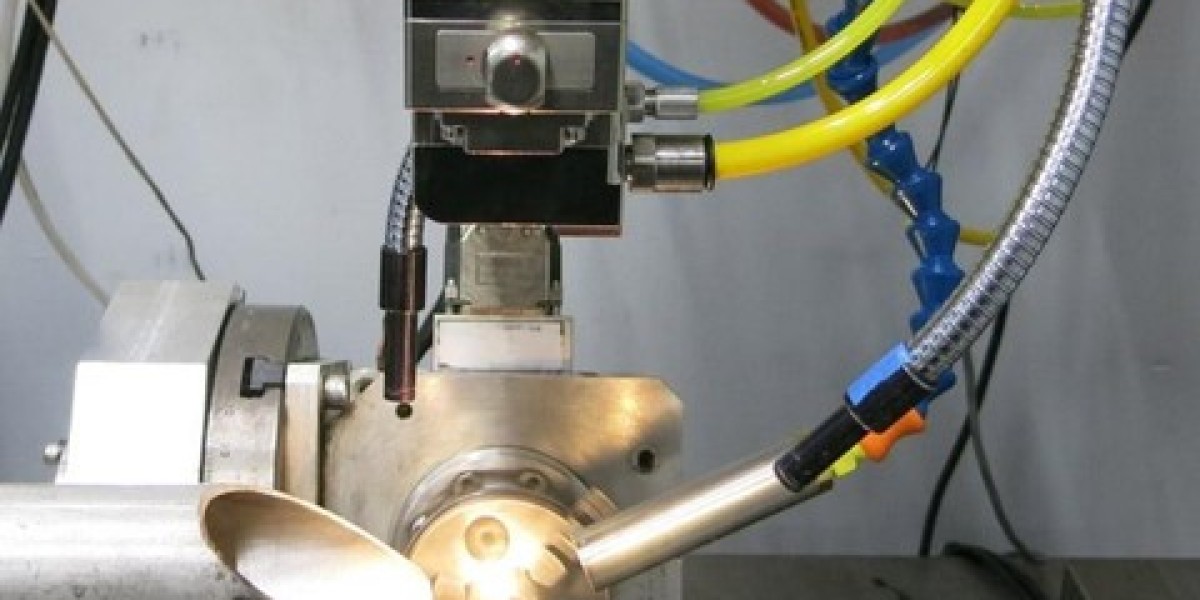

At LaserChina, we offer state-of-the-art laser beam welding tools engineered for performance and durability. Our systems are designed to handle a wide range of materials, including stainless steel, aluminum, titanium, and even dissimilar metals. Whether you need handheld devices for intricate work or automated systems for mass production, we have the perfect solution.

Key Features of Our Laser Welding Tools:

High-Power Fiber Lasers – For deep penetration and high-speed welding.

User-Friendly Interfaces – Intuitive controls for seamless operation.

Modular Designs – Customizable setups to fit your production needs.

Energy Efficiency – Lower power consumption without compromising performance.

Industries That Benefit from LaserChina’s Technology

Automotive: Perfect for welding car frames, battery components, and exhaust systems.

Aerospace: Ensures flawless joints in turbine blades and structural components.

Electronics: Ideal for delicate circuit boards and sensor assemblies.

Medical Devices: Provides contamination-free welds for surgical instruments.

Upgrade Your Production Line Today!

Why settle for outdated welding methods when LaserChina’s laser beam welding tool can take your manufacturing to the next level? Our solutions are built to enhance efficiency, cut costs, and deliver impeccable results—every time.

Visit LaserChina today and discover the future of welding technology!