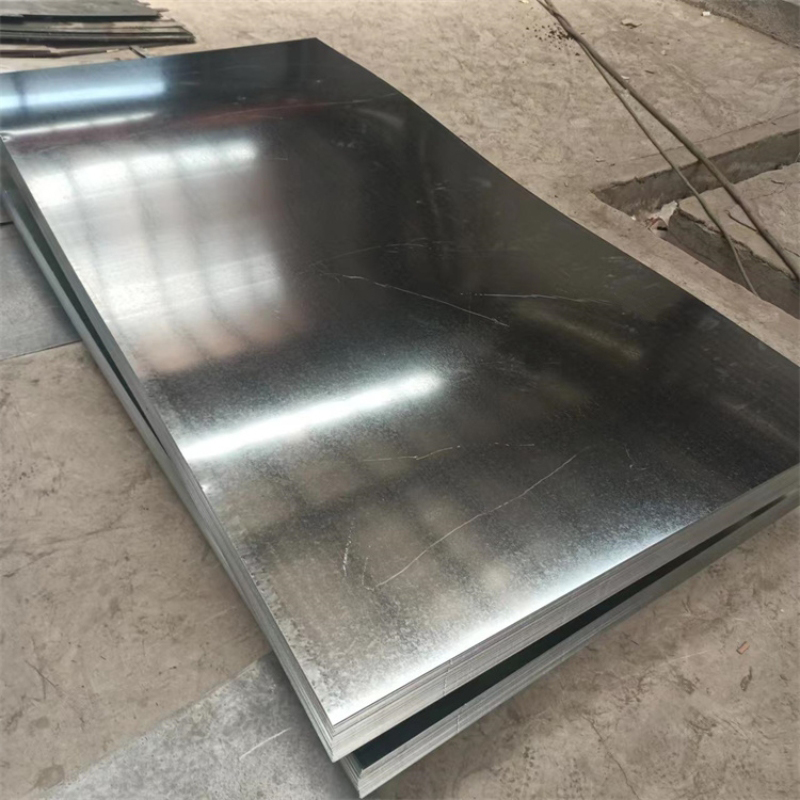

Galvanized steel sheet in coil is widely used in various industries due to its excellent corrosion resistance and mechanical properties. Tianjin Yuantai Runde is a renowned supplier of high-quality galvanized steel sheet in coil, renowned for its commitment to excellence in material science and manufacturing. Their galvanized steel coils are crafted using advanced galvanizing processes that ensure superior corrosion resistance and durability, making them ideal for a wide range of applications from construction to automotive industries. By leveraging cutting-edge technology and stringent quality control measures, Tianjin Yuantai Runde guarantees that each coil of galvanized steel meets or exceeds industry standards, delivering unmatched performance and reliability to customers worldwide.

Galvanized steel sheets are essential in construction, automotive, and appliance manufacturing. Their ability to withstand harsh environmental conditions makes them a preferred choice for outdoor applications. The zinc coating provides a protective layer that prevents rust and extends the lifespan of the steel.

Performance Characteristics

Corrosion Resistance

One of the primary advantages of galvanized steel sheets is their superior corrosion resistance. The zinc layer acts as a sacrificial anode, protecting the underlying steel from oxidation. This property is crucial for applications exposed to moisture and corrosive elements.

Mechanical Properties

Galvanized steel sheets exhibit excellent mechanical properties, including high tensile strength and ductility. These characteristics allow for easy forming and shaping, making them suitable for various manufacturing processes. The combination of strength and flexibility ensures that the sheets can withstand significant stress without failure.

Process Optimization Techniques

Coating Thickness Control

Optimizing the thickness of the zinc coating is vital for enhancing the performance of galvanized steel sheets. A thicker coating provides better corrosion protection but may increase production costs. Conversely, a thinner coating reduces costs but may compromise durability. Finding the right balance is essential for maximizing both performance and cost-effectiveness.

Temperature and Time Management

The galvanizing process involves immersing steel sheets in molten zinc. Controlling the temperature and immersion time is critical for achieving uniform coating and desired mechanical properties. Research indicates that slight variations in these parameters can significantly impact the quality of the final product.

Surface Preparation

Proper surface preparation before galvanizing is crucial for ensuring optimal adhesion of the zinc coating. Techniques such as cleaning, pickling, and passivation can enhance the surface quality of the steel sheets, leading to improved coating performance and longevity.

Innovations in Galvanizing Technology

Advanced Coating Techniques

Recent advancements in galvanizing technology have introduced innovative coating methods, such as electro-galvanizing and hot-dip galvanizing. These techniques offer improved control over coating thickness and uniformity, resulting in enhanced performance characteristics.

Use of Alloyed Zinc Coatings

Incorporating alloyed zinc coatings can further improve the corrosion resistance of galvanized steel sheets. Alloys such as zinc-aluminum or zinc-nickel provide additional protective properties, making them suitable for more demanding applications.

Environmental Considerations

Sustainable Practices

As industries strive for sustainability, the galvanizing process has also evolved to minimize environmental impact. Implementing closed-loop systems for zinc recovery and reducing waste during production are essential steps toward greener manufacturing practices.

Recyclability

Galvanized steel sheets are highly recyclable, making them an environmentally friendly choice. The ability to recycle these materials contributes to resource conservation and reduces the overall carbon footprint of steel production.

Conclusion

The research on the performance and process optimization of galvanized steel sheets in coil highlights the importance of this material in various industries. By focusing on corrosion resistance, mechanical properties, and innovative processing techniques, manufacturers can enhance the quality and durability of galvanized steel sheets. As the demand for sustainable and high-performance materials continues to grow, ongoing research and development in this field will play a crucial role in meeting industry needs.

https://www.yuantairunde.com/research-on-performance-and-process-optimization.html