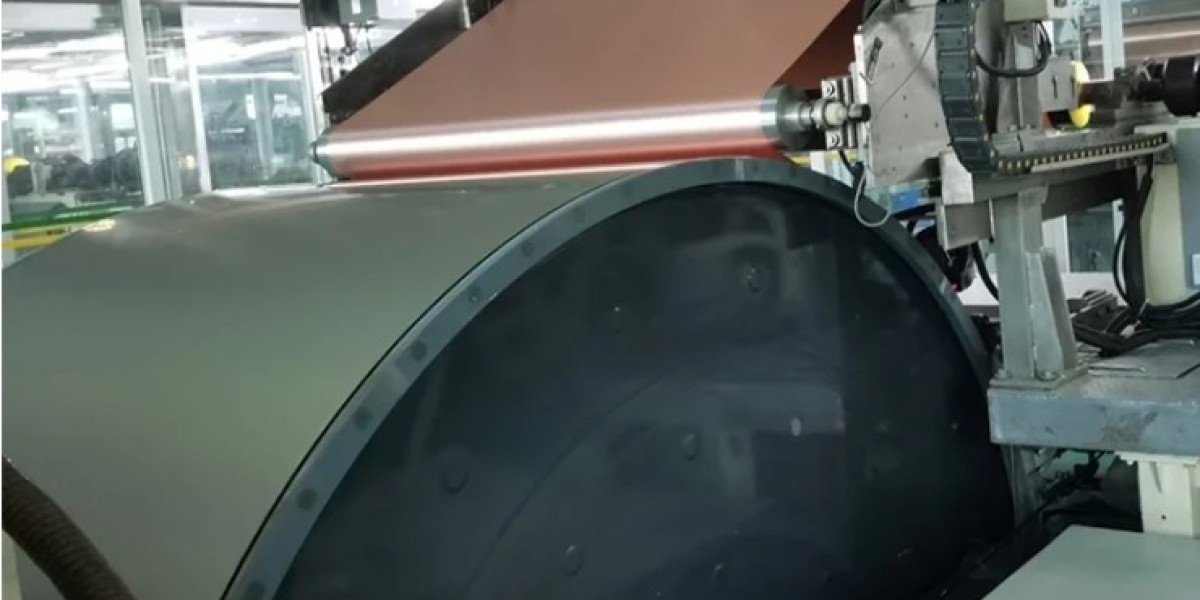

In the world of electronics, printed circuit boards (PCBs) play a crucial role in connecting and powering various components. The manufacturing process of PCBs requires precision and efficiency to ensure optimal performance. One key component that has revolutionized PCB manufacturing is electrode-posited copper foil equipment. In this article, we will explore the advantages of using this equipment and how it has transformed the industry.

I. Understanding Electrode-Posited Copper Foil Equipment

Electrode-posited copper foil equipment is a specialized machinery used in the production of copper foils for PCBs. It involves the electroplating process, where a thin layer of copper is deposited onto a conductive substrate, creating a uniform and high-quality copper foil. This equipment is available in various types, including continuous plating systems and reel-to-reel plating machines, each offering unique benefits for different manufacturing needs.

II. Enhanced Conductivity and Signal Integrity

One of the primary advantages of electrode-posited copper foil equipment is its ability to provide enhanced conductivity and signal integrity in PCBs. The electroplating process ensures a consistent copper thickness across the entire foil, eliminating variations that can lead to signal loss or distortion. Additionally, the smooth surface of the electrode-posited copper foil reduces surface roughness, minimizing signal reflection and improving overall signal transmission.

III. Increased Efficiency and Cost-Effectiveness

Electrode-posited copper foil equipment offers significant advantages in terms of efficiency and cost-effectiveness. The continuous plating systems allow for high-speed production, reducing manufacturing time and increasing productivity. Moreover, the precise control over the copper deposition process minimizes material waste, resulting in cost savings for manufacturers. By optimizing production efficiency and reducing material usage, electrode-posited copper foil equipment helps PCB manufacturers stay competitive in a fast-paced industry.

IV. Enabling Thinner and More Compact PCBs

The electrode-posited copper foil produced by this equipment enables the production of thinner and more compact PCBs. The copper foils can be manufactured with ultra-thin thicknesses, allowing for the creation of slim and lightweight circuit boards. This is particularly beneficial for applications where space is limited, such as mobile devices and wearables. Additionally, the electrode-posited copper foil offers improved flexibility, enabling the manufacturing of flexible and bendable PCBs.

V. Enhanced Thermal Management

Efficient heat dissipation is crucial for the reliable operation of electronic devices. Electrode-posited copper foil equipment plays a vital role in enhancing thermal management in PCBs. The high thermal conductivity of copper allows for effective heat transfer, preventing the buildup of heat and ensuring the optimal performance of components. By efficiently dissipating heat, electrode-posited copper foil equipment helps improve the reliability and longevity of electronic devices.

VI. Enabling High-Frequency Applications

With the increasing demand for high-frequency applications, electrode-posited copper foil equipment has become essential. The low insertion loss and reduced signal distortion offered by the high-quality copper foils enable the production of PCBs suitable for high-frequency circuits. This is particularly important for technologies like 5G and the Internet of Things (IoT), where reliable and high-speed signal transmission is critical.

VII. Environmental Sustainability

In addition to its technical advantages, electrode-posited copper foil equipment also promotes environmental sustainability. The electroplating process used in this equipment consumes less energy compared to traditional copper foil manufacturing methods. Furthermore, the precise control over the plating process reduces chemical usage, minimizing the environmental impact. Additionally, the copper foils produced by this equipment can be recycled and reused, further reducing waste and promoting a circular economy.

Conclusion

Electrode-posited copper foil equipment has revolutionized the PCB manufacturing industry by offering numerous advantages. From enhanced conductivity and signal integrity to increased efficiency and cost-effectiveness, this equipment has become a game-changer for manufacturers. Additionally, it enables the production of thinner and more compact PCBs, enhances thermal management, supports high-frequency applications, and promotes environmental sustainability. As technology continues to advance, electrode-posited copper foil equipment will play a crucial role in meeting the demands of the ever-evolving electronics industry.

How Electrode-Posited Copper Foil Equipment Enhances the Performance of Lithium-Ion Batteries