Circular Rails and Their Advantages

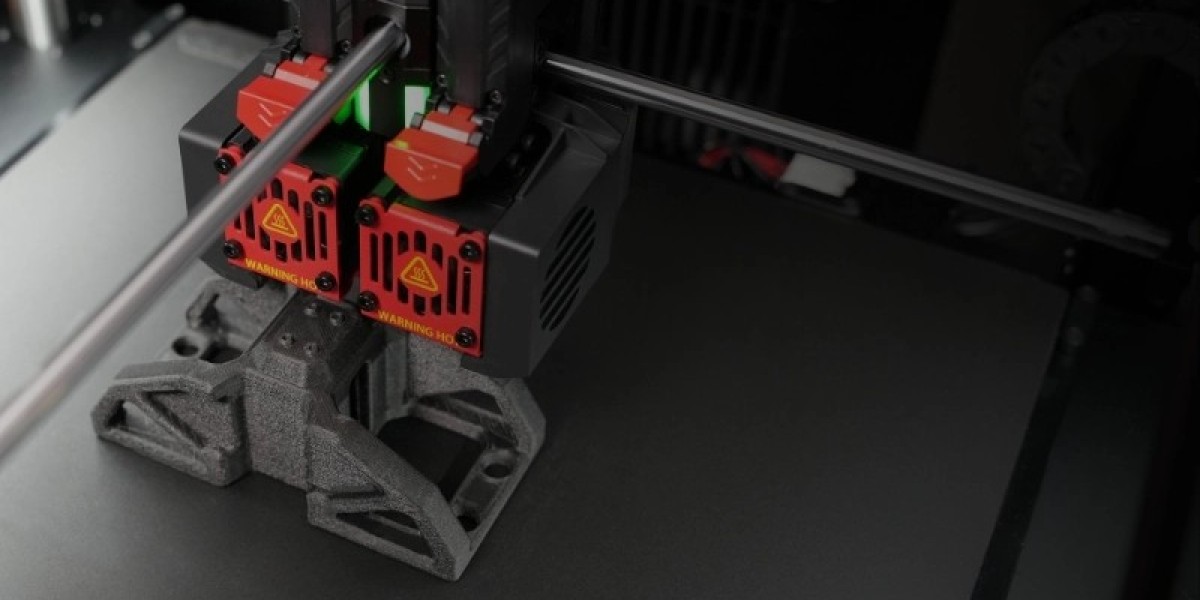

In the evolving landscape of 3D printing technology, the performance of equipment directly impacts printing precision and efficiency. Hithunder Group has launched a groundbreaking product: the Carbon Fiber Circular Rail. This innovative solution meets the industry's growing demands for lighter weight, higher load capacity, increased rigidity, better precision, and improved surface finish.

What are Circular Rails?

Circular rails are cylindrical rail systems designed to work with linear bearings and shafts. They can also be combined with sliders for a planar setup, making installation straightforward and space-efficient. Unlike traditional square rails, circular rails maintain smooth operation even on uneven surfaces, offering greater flexibility in various applications.

Features of Hithunder’s Carbon Fiber Circular Rail

The newly launched circular rail features:

- Dimensions: An outer diameter of 10.0 mm, inner diameter of 6.9 mm, wall thickness of 1.55 mm, and a length of 440.0 mm. Customization options are available to meet unique customer needs.

- High Load Capacity: The Z-axis of these carbon fiber circular rails is engineered for high load capacity while maintaining a low weight. This significantly reduces vibration and deflection errors.

- Precision Performance: The lightweight, fatigue-resistant X-axis rails exhibit minimal deformation, ensuring printing accuracy of ±0.2 mm or better. This enhancement boosts processing speeds while ensuring long-term high-precision performance.

Energy Efficiency and Cost Reduction

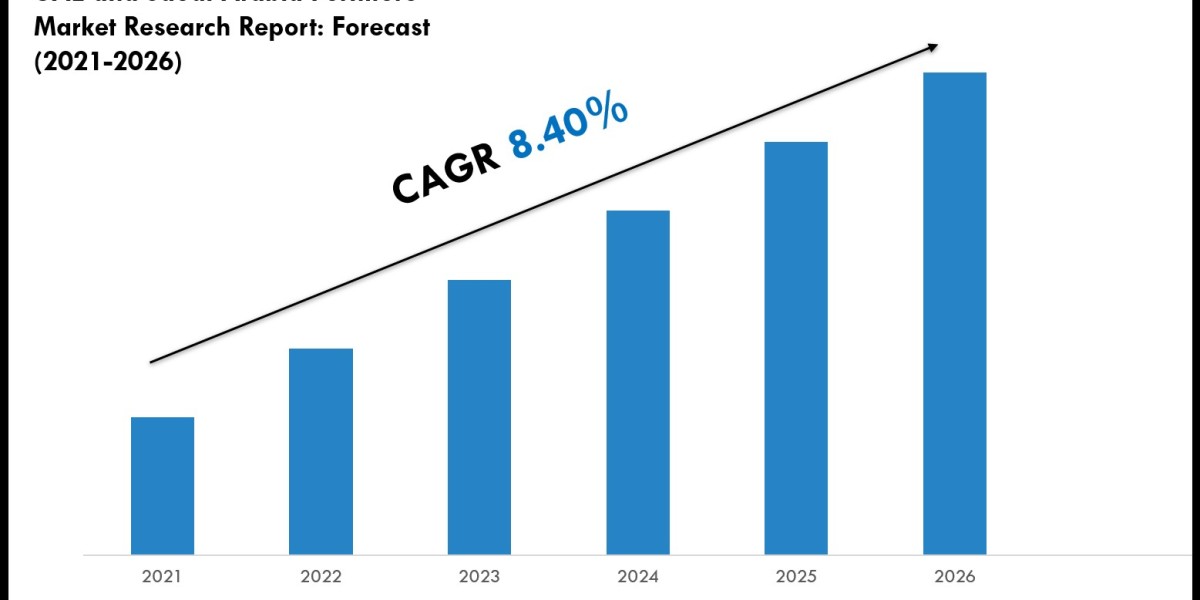

Using carbon fiber technology drastically reduces the weight of the equipment's moving parts, resulting in energy savings of 30% to 60% while maintaining the same printing quality. This not only lowers operational costs but also enhances the competitiveness of businesses in the market.

Conclusion

Hithunder's Carbon Fiber Circular Rail represents a significant leap in 3D printing technology. With its innovative use of carbon fiber materials, this product not only enhances printing precision and efficiency but also helps businesses reduce costs and improve overall performance. Choosing Hithunder means opting for high-performance, efficient, and competitive 3D printing solutions that meet the demands of the industry.