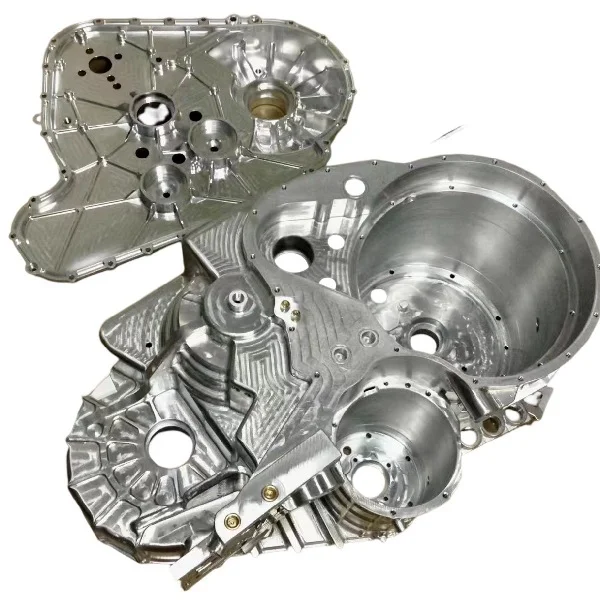

In today’s competitive industrial landscape, precision, customization, and performance consistency are no longer optional—they are strategic requirements. As manufacturing technologies evolve across sectors such as automotive, aerospace, energy, medical devices, and high-end automation, the demand for Non-standard Parts has grown at an unprecedented rate. These customized components, engineered to meet unique structural, functional, or environmental specifications, are reshaping how companies achieve efficiency and product differentiation.

Among the many suppliers in this rapidly shifting field, AICHI TECHNOLOGY has emerged as a trusted partner capable of delivering engineering-grade customization. By integrating advanced production systems, stringent quality standards, and cross-industry expertise, the company provides reliable non-standard solutions where conventional parts fall short.

1. Why Non-standard Parts Matter in Modern Manufacturing

Non-standard parts—also known as custom-engineered components—are designed when traditional catalog components cannot meet the performance, durability, or dimensional requirements of a project. The need typically arises in the following conditions:

① Complex mechanical constraints

Certain equipment layouts demand unique geometries, unconventional mounting structures, or special tolerances that standardized components cannot provide.

② Extreme operating environments

Industries such as mining, offshore energy, and high-temperature manufacturing require parts made from materials resistant to corrosion, abrasion, heat, or pressure.

③ Higher performance expectations

Next-generation systems often push the limits of speed, load, or precision. Custom components help engineers achieve superior alignment, rigidity, vibration control, or heat dissipation.

④ Integration with automated systems

Smart manufacturing relies on compatibility between sensors, actuators, and mechanical assemblies. Non-standard components ensure seamless integration with existing production lines.

As engineering moves toward specialization, non-standard parts have transitioned from niche solutions to critical enablers of industrial innovation.

2. The Engineering Logic Behind Non-standard Parts

Designing non-standard parts is a multidisciplinary process requiring collaboration between mechanical engineers, materials experts, and production specialists. The workflow typically includes:

• Technical Requirement Analysis

Engineers identify the exact stress profiles, tolerances, temperature ranges, and operational loads the part must withstand.

• Material Optimization

Depending on the application, options may include high-alloy steels, titanium, aluminum alloys, nickel-based superalloys, engineering plastics, or composite materials.

AICHI TECHNOLOGY’s materials database enables quick selection and verification based on fatigue limits, thermal expansion behavior, machining feasibility, and corrosion resistance.

• Precision Manufacturing

This often involves CNC machining, multi-axis milling, turning, EDM, forging, casting, laser cutting, or additive manufacturing.

AICHI TECHNOLOGY integrates automation with high-precision inspection, ensuring micron-level tolerances for complex geometries.

• Quality Assurance

Dimensional verification, surface roughness analysis, hardness testing, and finite element simulation (FEM/FEA) are applied to guarantee long-term stability.

Traceability and documentation ensure compliance with international standards such as ISO, ASTM, and DIN.

The process is both rigorous and highly specialized—one of the main reasons manufacturers depend on experienced providers rather than general-purpose machining workshops.

3. High-Value Applications Across Industries

Non-standard parts are used in thousands of engineering scenarios. Below are some high-value sectors where AICHI TECHNOLOGY frequently provides customized components.

Aerospace & Aviation

Lightweight structural elements, engine brackets, turbine components, precision bushings, and non-magnetic parts for sensors.

Custom geometry and heat-resistant materials ensure reliable performance under extreme vibration and temperature cycles.

Automotive & New Energy Vehicles (NEV)

High-strength connectors, drivetrain components, battery housing elements, and heat-transfer parts for EV platforms.

Non-standard components help manufacturers optimize weight, improve energy efficiency, and enhance durability.

Industrial Automation & Robotics

Gear sets, grippers, sensor housings, couplings, linear drive modules, and precision joints tailored to automation requirements.

Customized parts ensure accurate positioning, repeatability, and noise/vibration suppression.

Oil, Gas & Heavy Mining

Wear-resistant tools, reinforced structural components, corrosion-proof valves, and parts made with tungsten-carbide blends or hardened alloys.

Medical & Laboratory Equipment

High-precision stainless-steel components, sterilization-resistant assemblies, and functional prototypes.

Non-standard parts ensure compliance with strict safety and hygiene standards.

Across these fields, custom components often determine overall system reliability and competitive advantage.

4. Why Manufacturers Choose AICHI TECHNOLOGY for Non-standard Parts

AICHI TECHNOLOGY offers more than just machining services—it delivers engineering solutions. Core capabilities include:

• Full-chain engineering support

From concept evaluation to final production.

• Multi-process integration

Machining, casting, forging, stamping, and additive manufacturing in one system.

• Precision testing and certification

CMM measurement, laser scanning, material analysis, and fatigue inspection.

• Flexible production volumes

From prototypes to mass production, ensuring scalability for B2B clients.

• Strict quality control

Comprehensive documentation, batch control, and adherence to global standards.

• Cost-performance balance

Optimization of design and processing paths to achieve maximum performance with competitive pricing.

With its strong engineering team and advanced facilities, AICHI TECHNOLOGY continues to deliver stable, high-performance non-standard components to customers worldwide.

5. The Strategic Value of Non-standard Parts

As global industries shift toward high precision and intelligent manufacturing, the strategic value of non-standard parts will continue to grow:

They enable breakthrough product development

They shorten R&D cycles

They ensure operational stability

They reduce long-term maintenance costs

They support smart, digital, and connected manufacturing systems

In short, non-standard parts are no longer optional—they are foundational to next-generation industrial competitiveness.