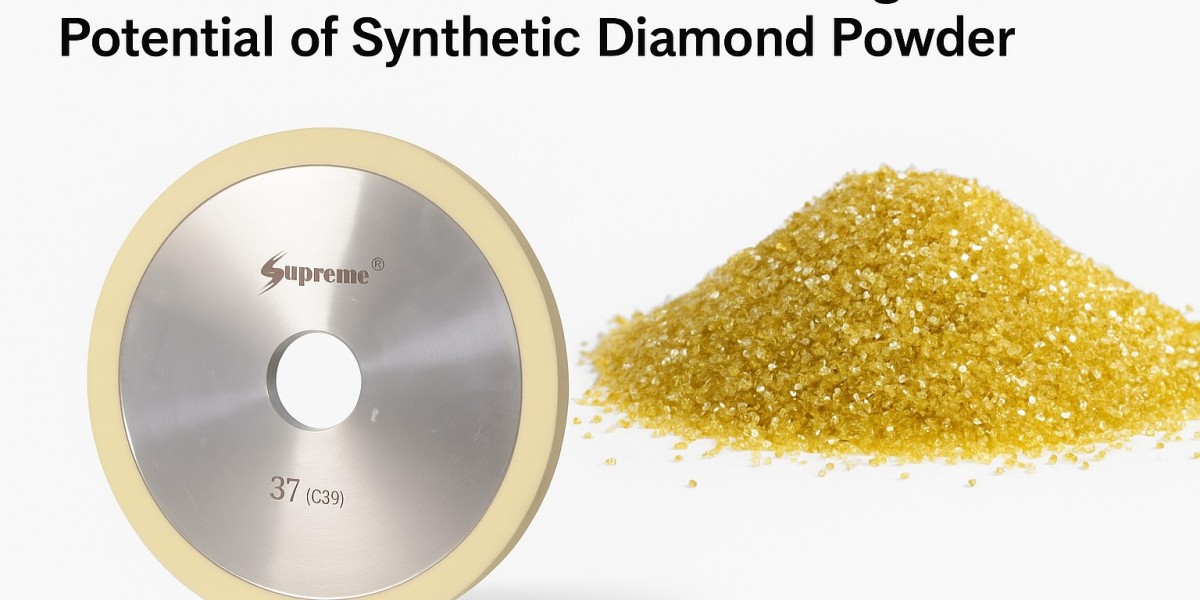

In the world of precision manufacturing and high-performance applications, few materials deliver the exceptional capabilities of synthetic diamond powder. This engineered marvel represents the pinnacle of abrasive technology, offering unmatched hardness, consistency, and versatility. At Supreme Abrasives, we've harnessed the power of this extraordinary material to provide industries with solutions that push the boundaries of what's possible in precision processing and surface finishing.

Understanding Synthetic Diamond Powder

Synthetic diamond powder consists of laboratory-grown diamond particles meticulously engineered to deliver superior performance characteristics. Unlike natural diamond alternatives, these manufactured powders offer exceptional purity, controlled particle size distribution, and consistent physical properties. Created through advanced technological processes that replicate the natural diamond formation environment, these powders deliver exceptional quality batch after batch, making them the preferred choice for precision-critical applications.

Key Advantages That Set It Apart

The exceptional properties of synthetic diamond powder make it indispensable across numerous industries:

Unmatched Hardness: Ranking 10 on the Mohs scale, it effortlessly processes the toughest materials including ceramics, carbides, and composites

Precise Particle Control: Engineered to specific micron sizes ensuring consistent, predictable results in every application

Thermal Stability: Maintains structural integrity and performance even under extreme temperature conditions

Chemical Inertness: Resists reaction with most materials, ensuring pure, contamination-free processing

Customizable Properties: Available in various particle shapes, surface chemistries, and size distributions to meet specific application requirements

Transformative Applications across Industries

Synthetic diamond powder serves as a critical component in numerous high-technology sectors:

Precision Grinding and Lapping: Essential for achieving micron-level tolerances and superior surface finishes in optical components, semiconductor wafers, and precision bearings

Advanced Coating Applications: Used in electroplated and CVD coatings for cutting tools, wear parts, and specialized components

Composite Material Enhancement: Reinforces polymers and metals to create advanced materials with exceptional durability and performance characteristics

Tool Manufacturing and Maintenance: Critical for producing and maintaining cutting tools, drill bits, and specialized industrial implements

Research and Development: Serves as a vital material in laboratories and R&D facilities pushing the boundaries of material science and manufacturing technology

The Supreme Abrasives Advantage

Our commitment to excellence ensures that every batch of synthetic diamond powder meets the most stringent quality standards. We provide:

Comprehensive range of micron sizes from coarse grinding to fine polishing applications

Exceptional particle consistency and controlled size distribution

Competitive pricing with uncompromised quality

Expert technical support and application guidance

Custom formulations for specialized requirements

Unlocking New Possibilities

For applications demanding the ultimate in precision, durability, and performance, synthetic diamond powder delivers unparalleled results. Its exceptional properties and reliability make it an indispensable resource for modern manufacturing and advanced technology development. Trust Supreme Abrasives to provide the quality, consistency, and expertise needed to harness the full potential of this remarkable material in your operations.