This technology has transformed how metal fabrication, automotive assembly, and aerospace component manufacturing are performed, ensuring durability and accuracy that traditional welding techniques often struggle to achieve.

Understanding the Concept of Laser Beam Welding

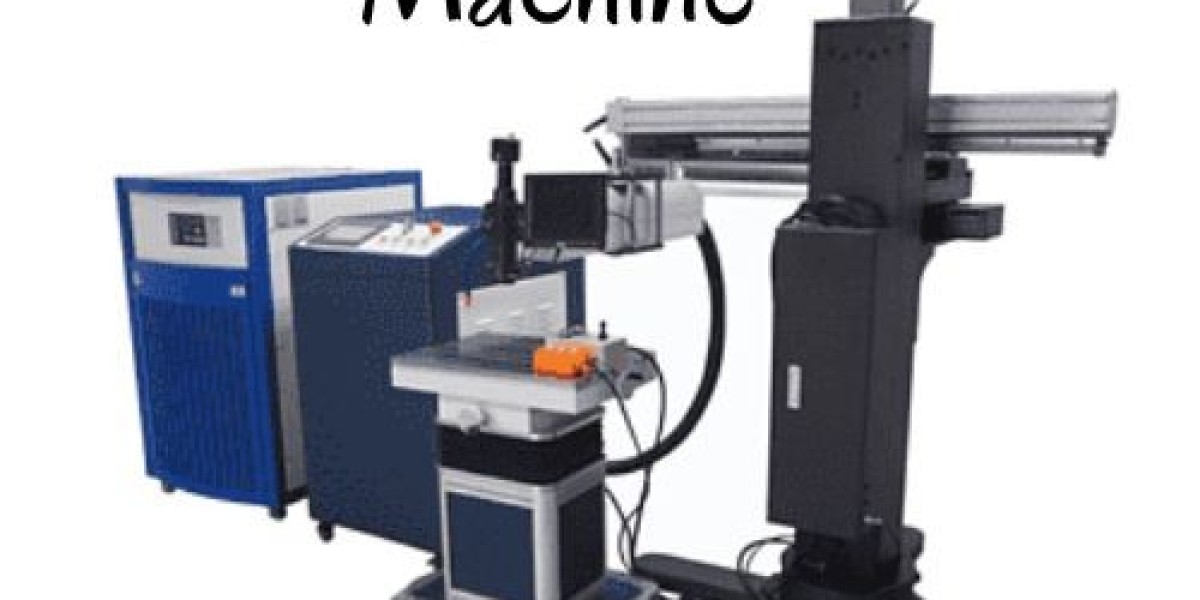

Laser beam welding, or LBW, is a fusion welding technique that uses a focused beam of light energy to join materials. The laser beam welding machine generates a concentrated source of heat, melting the metals at the joint area without extensive mechanical contact. This process creates a narrow, deep weld with minimal thermal distortion. Unlike arc or resistance welding, the laser’s energy density is far greater, allowing welding of both thin and thick materials with consistent quality.

The power of the laser is usually delivered through fiber optics, providing flexibility for both automated systems and robotic integration. As industries adopt smarter production methods, this adaptability makes laser beam welding a preferred choice for high-precision manufacturing.

Applications of the Laser Beam Welding Machine Across Industries

The versatility of the laser beam welding machine extends across multiple industrial sectors. In the automotive industry, it is used for welding car body parts, transmission components, and sensor housings. The precision allows manufacturers to achieve tight joint tolerances, ensuring safety and performance consistency.

In the aerospace sector, components like turbine blades, fuel injectors, and hydraulic parts require clean, accurate welds to withstand extreme conditions. The laser beam welding process guarantees minimal porosity and superior metallurgical integrity.

Medical device manufacturing also relies heavily on this technology. Devices such as pacemakers, surgical tools, and dental instruments require miniature welds with flawless finish and biocompatibility. The non-contact and contamination-free nature of laser welding meets these exact standards.

In electronics and micro-mechanics, where small and delicate parts must be joined with minimal heat impact, laser beam welding delivers precise control. It ensures reliable joints without damaging surrounding materials, which is essential for sensors, circuit boards, and micro-connectors.

The energy and engineering sectors further utilize this technology for battery welding, turbine repair, and fabrication of specialized equipment. The consistent output of the laser beam welding machine ensures efficiency in mass production without compromising weld integrity.

How the Laser Beam Welding Process Works

The operation of a laser beam welding machine follows a well-structured process. A high-energy laser beam is directed at the joint between two components. Depending on the material thickness and required weld depth, parameters such as beam power, speed, and focal point are adjusted precisely.

The process can operate in two primary modes: conduction welding and keyhole welding.

In conduction mode, the laser energy melts the surface, creating a shallow weld with a smooth finish.

In keyhole mode, the laser intensity is so high that it vaporizes the material, forming a narrow and deep penetration weld.

Modern laser beam welding machines often integrate CNC systems or robotic arms, enabling automated and repeatable welding cycles. Sensors and monitoring software control the process parameters in real-time, maintaining uniform weld quality. This automation not only enhances accuracy but also significantly reduces material waste and production downtime.

Why Industries Are Moving Toward Laser Beam Welding Machines

With rising demands for lightweight structures and complex geometries, industries need a welding method that ensures both mechanical strength and aesthetic quality. The laser beam welding machine meets these requirements effectively.

It supports high-speed operation with reduced post-processing, minimizing production time. The precision of the laser reduces material distortion, allowing engineers to work with thinner metals and achieve higher component integrity.

The energy efficiency of the laser system also contributes to sustainability. Compared to conventional welding, less filler material and shielding gas are required, resulting in a cleaner and environmentally responsible process.

Moreover, the laser beam welding machine can handle a broad range of materials—stainless steel, aluminum, titanium, copper, and even advanced alloys—making it suitable for hybrid and composite assemblies. This flexibility allows manufacturers to experiment with innovative designs and structures without sacrificing strength or performance.

Automation and Digital Integration in Modern Laser Beam Welding Machines

One of the most transformative aspects of modern manufacturing is automation. The laser beam welding machine integrates seamlessly into robotic production lines, making it ideal for continuous and high-volume operations.

Digital systems provide precise control over laser parameters and enable integration with CAD/CAM design tools. Real-time monitoring systems analyze each weld through sensors and cameras, ensuring defects are detected instantly. These advancements make the process reliable, repeatable, and scalable.

Artificial intelligence and machine vision technologies are increasingly being used to improve seam tracking, adaptive focusing, and quality control. The result is a fully automated welding solution that enhances throughput and product consistency.

Maintenance and Operational Efficiency

Proper maintenance plays a crucial role in maximizing the performance of a laser beam welding machine. Regular cleaning of optical lenses, mirrors, and protective glass ensures consistent beam quality. Cooling systems and power supplies should be checked periodically to prevent performance fluctuations.

The alignment of the beam delivery system must also be verified to maintain accuracy. Many modern laser systems come equipped with self-diagnostic software that alerts operators to potential issues before they cause downtime. Preventive maintenance schedules not only prolong machine lifespan but also maintain the consistency required in precision welding applications.

Operator training is equally vital. Skilled technicians can optimize parameters based on different materials and joint types, enhancing overall process reliability. As the technology evolves, continuous learning and adherence to safety protocols are essential.

Environmental and Economic Impact

The laser beam welding machine supports sustainable manufacturing through its efficient energy usage and reduced waste. The process produces minimal fumes and spatter, contributing to cleaner work environments. Additionally, the reduced need for consumables and rework makes it cost-effective over long-term production cycles.

As industries prioritize sustainability, adopting technologies like laser welding aligns with environmental goals without compromising productivity. The reduction in energy consumption and material wastage also improves overall profitability, creating a win-win scenario for both manufacturers and the environment.

Future of Laser Beam Welding Machines

The evolution of laser beam welding machines continues with innovations in beam quality, power modulation, and control precision. Fiber lasers have already improved efficiency and reliability, but future developments aim for even finer control and faster processing speeds.

Integration with Industry 4.0 systems, data analytics, and smart sensors will allow predictive maintenance and adaptive process optimization. These advancements will make laser welding systems indispensable in advanced manufacturing, from electric vehicle production to aerospace innovation.

As additive manufacturing and hybrid welding techniques become more prevalent, the laser beam welding machine will play a vital role in combining different materials and creating stronger, lighter structures. The synergy between digital control and material science will continue to redefine what’s possible in welding technology.

Final Thoughts

The laser beam welding machine has redefined precision joining for industries demanding accuracy, speed, and consistency. Its ability to deliver clean, deep welds with minimal heat distortion makes it an essential part of modern fabrication systems. From micro-components to heavy-duty industrial structures, its reliability and adaptability are unmatched.

As industries advance toward smarter and more efficient manufacturing, the role of laser beam welding will only expand. Investing in this technology today means embracing the future of manufacturing—one built on precision, automation, and lasting performance.