A laser nozzle is the final outlet that shapes and controls the flow of assist gas, such as oxygen, nitrogen, or air, during the laser cutting process. Positioned directly under the focusing lens, it ensures that both the laser beam and gas are properly aligned toward the workpiece. This alignment is crucial for maintaining cutting precision, preventing oxidation, and ensuring efficient removal of molten material.

The nozzle also acts as a protective barrier between the optical components and the harsh environment created during cutting. It keeps debris, smoke, and splatter away from the focusing lens, preserving the system’s efficiency and reducing maintenance intervals.

Types of Laser Nozzles Used in Industrial Applications

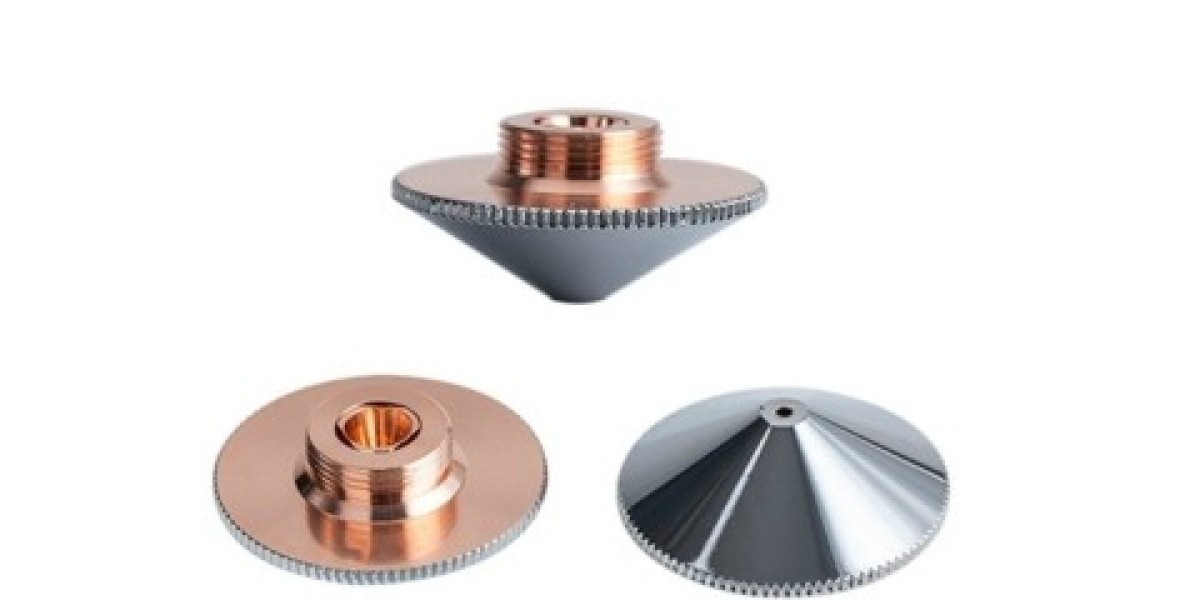

Laser nozzles come in several configurations, each designed to serve a specific purpose. The two most common types are single-layer and double-layer nozzles.

Single-layer nozzles are often used for oxygen-assisted cutting. They allow high gas flow rates that support the oxidation process, enhancing the speed of carbon steel cutting.

Double-layer nozzles, on the other hand, are typically used for nitrogen or air-assisted cutting, especially in stainless steel or aluminum applications where oxidation must be avoided.

The nozzle diameter, length, and taper also vary depending on the laser cutting head and material requirements. Selecting the right laser nozzle type ensures consistent results and optimal performance for each material type.

How Laser Nozzle Design Affects Cutting Performance

The geometry and dimensions of the laser nozzle have a direct impact on the gas flow, beam focus, and edge quality. A small misalignment between the laser beam and nozzle can cause beam distortion, uneven cuts, or excessive dross formation. Precision in nozzle manufacturing, therefore, becomes a key factor for maintaining stable performance.

Nozzle diameter determines gas pressure and flow distribution. For thin materials, smaller nozzles are preferred to achieve narrow kerfs and clean cuts. In contrast, thicker materials require larger nozzles that allow higher gas flow for efficient molten material removal.

Even the smallest irregularities in nozzle shape can influence gas dynamics, causing turbulence or asymmetrical flow. That’s why high-precision laser cutting operations rely on nozzles manufactured through advanced CNC machining and strict quality inspection processes.

Materials Used in Laser Nozzle Manufacturing

The laser nozzle must withstand high temperatures, pressure variations, and exposure to molten particles. To meet these demands, manufacturers use durable materials like copper, brass, and ceramic-coated alloys.

Copper nozzles are widely used because of their excellent thermal conductivity and electrical properties, which minimize heat buildup and allow consistent gas delivery.

Brass nozzles provide good wear resistance and cost efficiency for less demanding tasks.

Some high-end nozzles feature ceramic coatings or inserts that enhance durability and resist oxidation during high-power cutting operations.

Material choice directly impacts nozzle life, gas flow stability, and maintenance requirements. Consistent performance depends on using nozzles that match the machine’s power, gas type, and operational environment.

Nozzle Alignment and Calibration in Laser Cutting Systems

Precise alignment between the laser nozzle and the laser beam is essential for achieving consistent results. Misalignment can lead to beam reflection, irregular cutting edges, and reduced efficiency. During installation or nozzle replacement, operators perform nozzle centering tests to ensure the laser beam passes perfectly through the center of the nozzle orifice.

Modern laser cutting machines use automatic calibration systems that detect and adjust nozzle alignment with high precision. These systems ensure that the assist gas flow and beam focus remain consistent even after long operating hours or nozzle changes. Maintaining accurate alignment reduces scrap rates and enhances production efficiency.

Gas Flow Dynamics and Its Connection to Laser Nozzle Design

The laser nozzle regulates how assist gas interacts with the molten pool during cutting. This gas flow not only removes molten material but also cools and protects the cut edges from oxidation. The shape and size of the nozzle orifice determine the flow velocity and pressure distribution.

For example, when using nitrogen gas, uniform flow ensures bright, oxidation-free edges, especially in stainless steel cutting. In contrast, oxygen flow through the nozzle promotes chemical reactions that accelerate cutting speed for carbon steels. The laser nozzle must be designed to handle these flow dynamics without causing turbulence or backpressure that could disrupt the cutting beam.

Proper nozzle design allows for optimal gas efficiency, which is increasingly important for industries aiming to minimize operating costs without compromising on quality.

Common Problems Related to Laser Nozzle Wear

During continuous operation, laser nozzles can wear out due to heat, debris impact, or oxidation. This wear changes the nozzle’s internal geometry, causing irregular gas flow and unstable cutting conditions. Common symptoms of nozzle wear include rough edges, inconsistent penetration, or excessive slag formation.

Regular inspection and timely replacement of worn nozzles prevent quality issues and costly downtime. Many workshops maintain a set replacement schedule depending on the type of material processed and the machine’s workload. Using damaged nozzles can also put the focusing lens at risk, as gas flow turbulence may redirect molten particles upward.

Cleaning and Maintenance of Laser Nozzles

Proper maintenance of the laser nozzle ensures consistent performance and longer service life. Nozzles should be cleaned regularly to remove dust, metal splatter, or oxidation residues. Using a non-abrasive cleaning solution and soft brushes helps preserve the nozzle’s internal surface and prevents distortion.

Many modern laser cutting systems feature automatic nozzle cleaning stations that use compressed air or brushes between cutting cycles. This automation reduces manual labor and helps maintain consistent gas flow characteristics. Additionally, using precision measurement tools to check nozzle concentricity after cleaning helps confirm it is ready for high-quality operation.

Compatibility Between Nozzle and Laser Head

Each laser nozzle is designed to match specific laser head models and cutting parameters. Using incompatible nozzles can lead to misalignment, reduced gas efficiency, or even damage to the focusing lens. Therefore, it is essential to select nozzles recommended by the machine manufacturer or verified third-party suppliers with matching specifications.

Compatibility also extends to assist gas types and pressures. The same nozzle may behave differently with oxygen or nitrogen due to variations in flow behavior. Ensuring full compatibility between the laser head, nozzle, and gas system is key to maintaining cutting stability and quality consistency.

Latest Innovations in Laser Nozzle Technology

Advancements in laser nozzle technology are reshaping how manufacturers approach precision cutting. Modern nozzles feature improved internal flow geometry, anti-spatter coatings, and adaptive designs that automatically adjust to gas pressure changes. Some high-end systems use sensors that monitor nozzle condition and alert operators when cleaning or replacement is required.

3D laser cutting systems also utilize specially designed nozzles capable of maintaining consistent gas flow even when cutting complex angles or curved surfaces. These innovations not only enhance accuracy but also improve operational efficiency across different industries, from automotive to aerospace.

Applications of Laser Nozzles in Industrial Environments

The laser nozzle is an integral part of numerous laser-based processes including cutting, welding, engraving, and surface treatment. In automotive manufacturing, it ensures clean and precise cuts for body panels and chassis components. In electronics and precision engineering, nozzles help achieve micro-level accuracy when cutting thin materials.

Construction, shipbuilding, and metal fabrication industries also depend on high-quality nozzles for continuous, stable production. Whether the process involves mild steel, stainless steel, or aluminum, the right nozzle selection supports consistent cutting results and reduced operational costs.

Final Thoughts

The laser nozzle may appear as a small and simple component, yet it plays a central role in ensuring accuracy, stability, and quality in laser cutting operations. Its design, alignment, and maintenance determine how effectively a laser system performs under demanding industrial conditions. By understanding its structure and operational principles, manufacturers can achieve superior results, minimize downtime, and maintain optimal production efficiency. The right laser nozzle doesn’t just control the gas flow—it shapes the entire outcome of the cutting process.