In industries such as pharmaceuticals, food, and daily chemicals, the safety and reliability of packaging directly influence product quality and consumer trust. Vials and ampoules are widely used to store liquids, powders, and injectable products, but their small size and fragile structure make them prone to defects. Detecting these defects early is crucial for ensuring compliance, protecting brand reputation, and safeguarding patient and consumer safety.

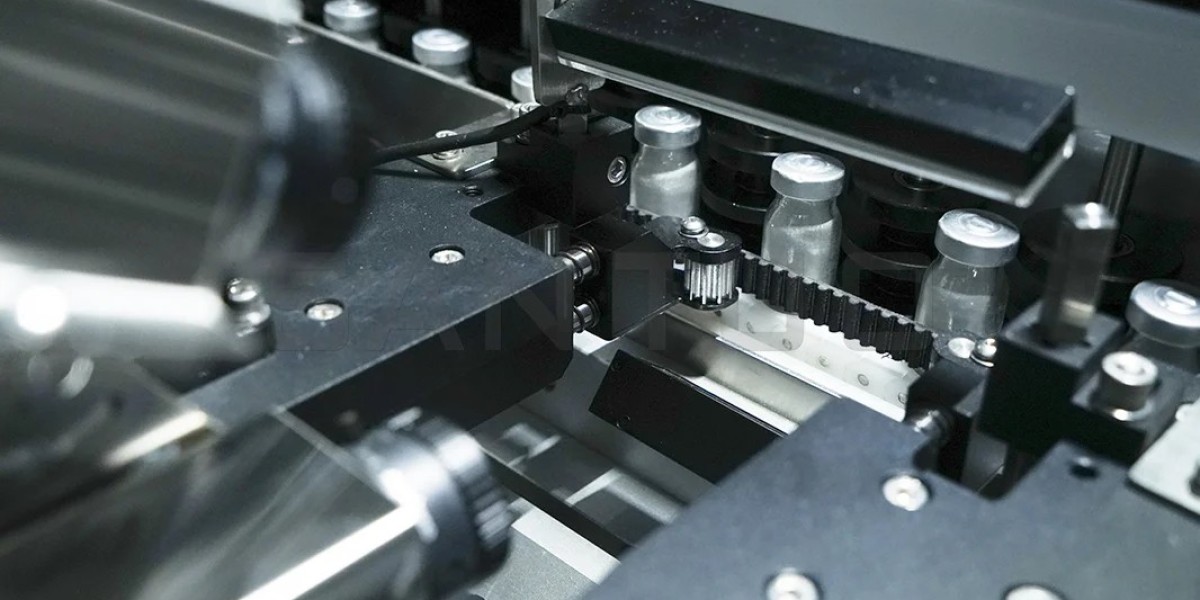

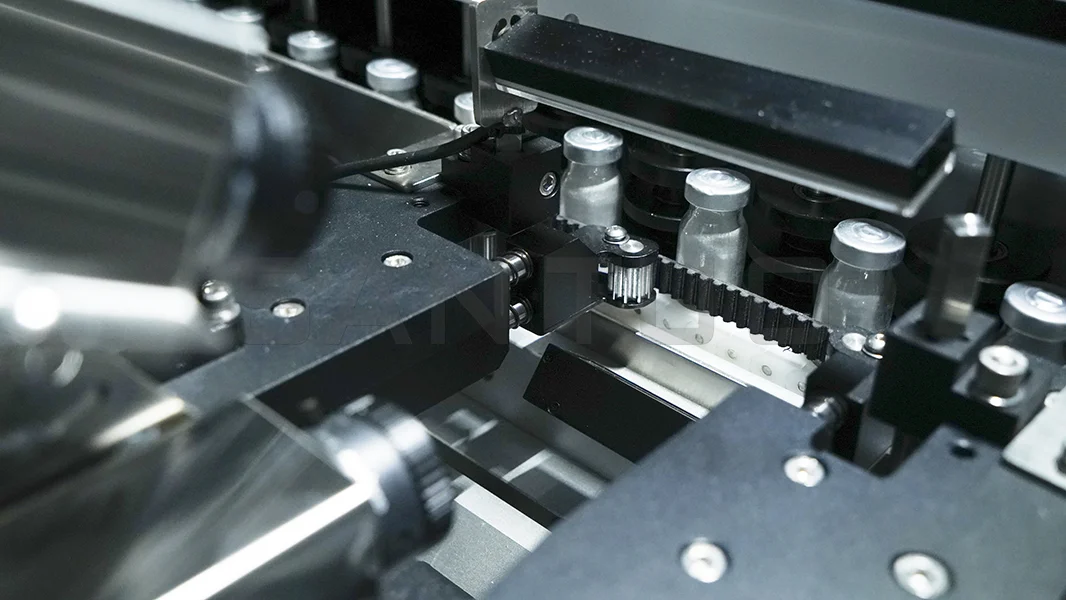

The Dual-channel Vial Inspection Machine offers a highly effective solution for this challenge, combining advanced inspection technology with operational efficiency.

Challenges in Vial and Ampoule Quality Control

Manual inspection of vials and ampoules is time-consuming and often inconsistent. Small cracks, foreign particles, or misapplied caps may escape visual detection, leading to risks such as contamination, dosage inaccuracies, or product recalls. Manufacturers need an automated system that provides reliable, repeatable, and efficient inspection across high-volume production lines.

Key Inspection Capabilities

The Dual-channel Vial Inspection Machine is designed to cover a comprehensive range of inspection points, ensuring no defect is overlooked:

· Cap inspection – Detects damage to the cap, rubber stopper, aluminum seal, or plastic cap.

· Vial body inspection – Identifies cracks, scratches, black spots, and checks the fill level.

· Vial bottom inspection – Detects cracks, foreign objects, and contamination at the base.

· Foreign object detection – Locates black spots or particles on the powder’s surface and inside the vial body.

This multi-angle inspection ensures the integrity of both the container and its contents.

Operational Advantages

Beyond its inspection scope, the Dual-channel Vial Inspection Machine is engineered for practical use in modern factories:

· Easy product changeover – Compatible with different types of round vials. Quick-release molds reduce downtime when switching products.

· High safety standards – Equipped with shields, doors, and switches that comply with CE certification.

· Stable and efficient operation – Intelligent algorithms deliver reliable results while maintaining high throughput.

· System integration – PLC with optional network interface enables seamless connection with MES, ERP, and other production software.

These features not only improve inspection accuracy but also help manufacturers streamline workflows and achieve digitalized production.

Applications Across Industries

The machine is widely used in:

· Pharmaceuticals – injectable vials, ampoules, and lyophilized powder.

· Food and Beverage – flavoring liquids, nutrition vials, health supplements.

· Daily Chemicals – cosmetic serums, essential oils, and chemical reagents.

Its broad compatibility ensures versatility for companies handling diverse product lines.

Conclusion

The Dual-channel Vial Inspection Machine addresses one of the most pressing challenges in vial and ampoule packaging: ensuring defect-free, safe, and compliant products. By automating appearance inspection and foreign object detection, it eliminates human error, boosts efficiency, and strengthens overall quality assurance.

For industries where safety and precision cannot be compromised, this technology offers a reliable way to maintain trust, meet regulatory standards, and optimize production performance.