IMARC Group, a leading market research company, has recently releases a report titled “Industrial Agitators Market Report by Type (Industrial Stirrer, Paint Mixers, High Speed Stirrers, Chemical Agitators, Others), Mounting Type (Top-mounted, Side-mounted, Bottom-mounted), Distribution Channel (Online, Offline), Industry Vertical (Chemicals and Paints, Material and Construction, Food and Beverages, Pharmaceutical, Consumer Goods, and Others), and Region 2025-2033.” The study provides a detailed analysis of the industry, including the global industrial agitators market size, share, trends and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Industrial Agitators Market Highlights:

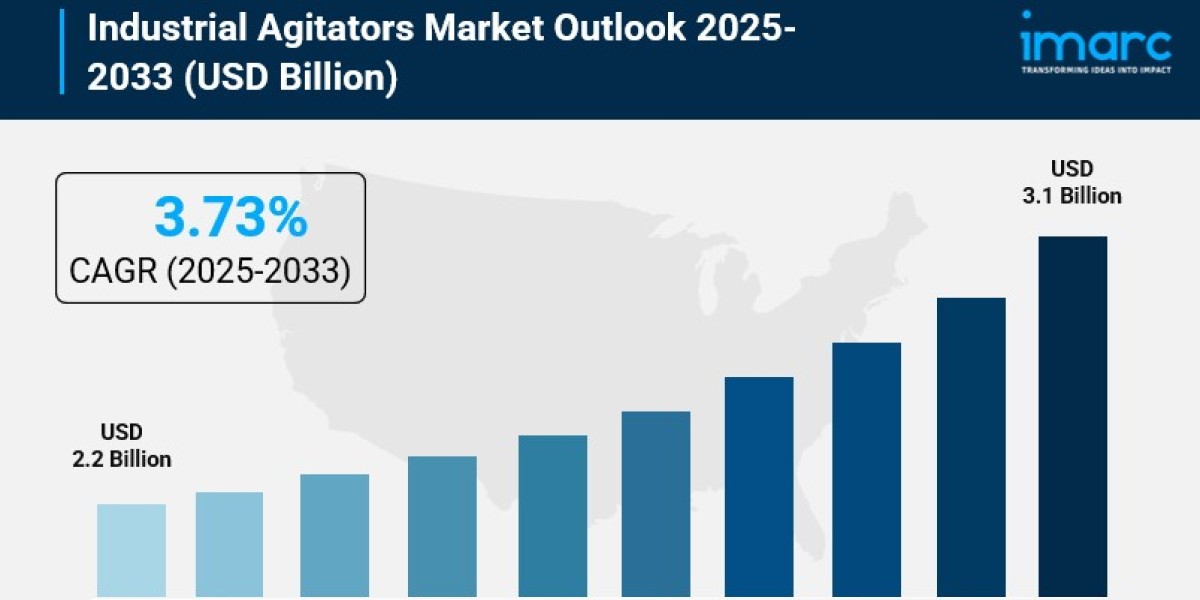

- Industrial Agitators Market Size: Valued at USD 2.2 Billion in 2024.

- Industrial Agitators Market Forecast: The market is expected to reach USD 3.1 billion by 2033, exhibiting a growth rate (CAGR) of 3.73% during 2025-2033.

- Market Growth: The industrial agitators market is projected to experience significant growth due to increasing demand in various industries.

- Applications: Key applications include chemical processing, food and beverage, pharmaceuticals, and wastewater treatment.

- Types: Various types of agitators are available, including mechanical, magnetic, and hydraulic agitators.

- Regional Insights: North America and Europe are leading markets, driven by advanced manufacturing and technological innovations.

- Trends: Growing emphasis on energy efficiency and automation in industrial processes is shaping market dynamics.

- Competitive Landscape: The market features several key players focusing on product innovation and strategic partnerships.

- Challenges: High initial investment and maintenance costs are significant challenges for market growth.

- Future Outlook: The market is expected to expand as industries increasingly adopt advanced mixing technologies to enhance production efficiency.

- Request for a sample copy of the report: https://www.imarcgroup.com/industrial-agitators-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Industry Trends and Drivers:

- Increasing Demand in Chemical and Pharmaceutical Processing:

A primary driver for the industrial agitators market is just the expanding need for more efficient mixing along with blending in both pharmaceutical and chemical industries. In chemical manufacturing, agitators are critical for processes such as polymerization, crystallization, together with fermentation because they ensure consistent product quality and reaction kinetics across massive batch volumes. New petrochemical plants along with specialty chemical production facilities do increase the demand through construction, most notably in emerging markets, and these require that a fleet of high-performance agitators must be reliable. Precision is of even more need in both biotechnology and pharmaceutical sectors. Agitators remain necessary during drug and vaccine development for preparing media plus buffers or mixing complex bioreactors. Stringent regulatory requirements for product purity, sterility, and consistency create a strong non-negotiable demand for advanced mixing solutions via the use of advanced agitators.

- Focus on Process Optimization and Energy Efficiency:

Process optimization, automation, as well as energy efficiency are a pervasive sort of trend. This trend is just another meaningful catalyst for the industrial agitators market. Modern manufacturing facilities focus intensely on reducing operational expenditure (OPEX). Their mixing processes' overall efficiency also sees improvement. This demands agitators use advanced impeller designs as well as high-efficiency motors in order to mix properly plus consume greatly less power than legacy models. The integration of agitator systems with control platforms allows for the monitoring in real time. DCS and SCADA, advanced platforms, allow automated speed adjustments using process variables like temperature and viscosity. This is a trend that requires that people adopt smart, connected agitators equipped with sensors and also variable frequency drives (VFDs). Due to the fact it reduces energy bills and optimizes batch cycle times, end-users do highly prioritize investment in automated agitator systems across heavy industries.

- Expansion of Food, Beverage, and Water Treatment Applications:

The third major driver is the sustained growth within the food and beverage (F&B) sector. Critical needs exist as well in the water and wastewater treatment (WWT) industry. In F&B, agitators are indispensable for blending ingredients such as sauces, dairy products, together with syrups. They do also maintain at all times the consistency of liquid suspensions. Hygienic, sanitary agitator designs preventing bacterial buildup and complying with food safety standards are directly fueled by growth of global packaged food consumption combined with increasing demand for diverse beverage formulations (like plant-based milks and RTD products). Likewise, the WWT sector requires powerful agitators since they mix chemicals during flocculation, aeration, and sludge processing. Populations grow plus environmental regulations increase worldwide so meaningful investment in new WWT infrastructure is necessary creating a consistent long-term demand for durable industrial agitators capable of handling huge volumes of liquid materials.

Industrial Agitators Market Report Segmentation:

Breakup by Type:

- Industrial Stirrer

- Paint Mixers

- High Speed Stirrers

- Chemical Agitators

- Others

Breakup by Mounting Type:

- Top-mounted

- Side-mounted

- Bottom-mounted

Breakup by Distribution Channel:

- Online

- Offline

Breakup by Industry Vertical:

- Chemicals and Paints

- Material and Construction

- Food and Beverages

- Pharmaceutical

- Consumer Goods

- Others

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Who are the key players operating in the industry?

The report covers the major market players including:

- Dynamix Agitators Inc.

- EKATO Holding Gmbh

- Mixer Direct

- NOV Inc.

- Silverson

- SPX FLOW Inc.

- Statiflo International Ltd.,

- Sulzer Ltd

- TACMINA CORPORATION

- Xylem Inc.

Ask Analyst For Request Customization: https://www.imarcgroup.com/request?type=report&id=4605&flag=E

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302