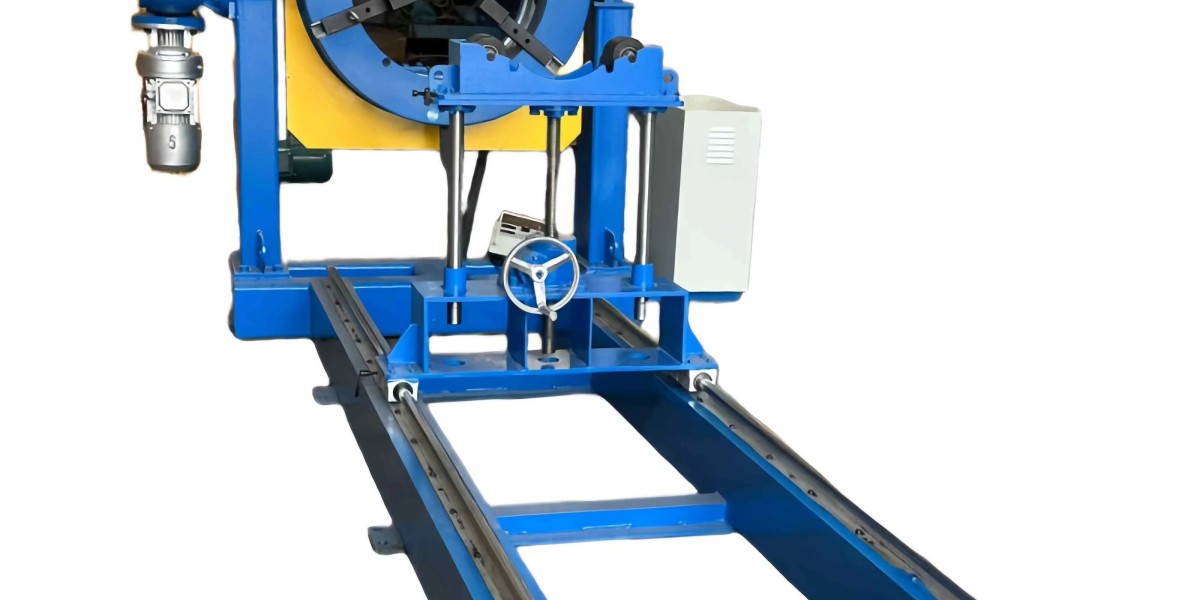

In the realm of industrial welding, efficiency and precision are paramount. The 2-Axis welding positioner stands out as a pivotal piece of equipment that significantly enhances welding operations, particularly in pipe welding applications. This sophisticated machinery is engineered to meet the demands of modern welding processes, ensuring consistency and high-quality welds.

Core Features and Benefits

Precision Engineering for Optimal Performance

The 2-Axis welding positioner is a precision-engineered solution designed for pipe welding applications. Its dual-axis rotation and tilting capabilities set it apart, offering unparalleled versatility in positioning pipes for welding. This precision engineering ensures that pipes can be positioned at any angle, facilitating access to even the most difficult-to-reach welding spots.

Dual-Axis Rotation and Tilting Capabilities

One of the standout selling points of the 2-Axis welding positioner is its dual-axis functionality. The ability to rotate and tilt the workpiece independently allows operators to achieve the perfect welding position every time. This not only improves welding accuracy but also enhances operator safety by reducing the need for awkward or unsafe postures.

Rotation Axis: Enables 360-degree rotation of the pipe, allowing welders to access all circumferential welds with ease.

Tilting Axis: Provides adjustable tilt angles, which are crucial for welding pipes at various inclinations, such as in horizontal-to-vertical or vertical-to-overhead positions.

Consistent, High-Quality Welds

Optimal positioning is key to achieving consistent, high-quality welds. The 2-Axis welding positioner ensures that pipes are held steady and accurately positioned throughout the welding process. This stability minimizes weld defects such as porosity, undercut, and spatter, leading to stronger, more reliable welds.

Improved Weld Appearance: Precise positioning results in uniform bead appearance and reduced weld distortion.

Enhanced Structural Integrity: High-quality welds contribute to the overall strength and durability of welded assemblies.

Enhanced Productivity and Efficiency

Streamlined Workflow

The 2-Axis welding positioner streamlines welding workflows by automating the positioning of pipes. This automation reduces setup time and eliminates the need for manual adjustments, thereby increasing overall productivity.

Rapid Positioning: Operators can quickly and easily adjust the positioner to the desired angles, minimizing downtime between welds.

Multi-Tasking Capabilities: With the pipe securely positioned, welders can focus on the welding process itself, rather than on manual adjustments.

Improved Operator Ergonomics

The design of the 2-Axis welding positioner also takes operator ergonomics into account. By enabling a more comfortable welding position, it reduces operator fatigue and the risk of injury.

Adjustable Work Height: The positioner can be adjusted to different heights to accommodate various operator preferences and work environments.

Ergonomic Controls: Intuitive controls make it easy for operators to adjust the positioner with minimal effort.

Applications and Versatility

The versatility of the 2-Axis welding positioner makes it suitable for a wide range of applications. From the fabrication of industrial equipment to the construction of pipelines, this machinery is indispensable in various industries.

Industrial Fabrication

In industrial fabrication settings, the 2-Axis welding positioner is essential for welding large-diameter pipes and complex assemblies. Its precision and versatility ensure that welds meet stringent quality standards, contributing to the overall reliability and performance of fabricated products.

Pipeline Construction

In pipeline construction, the ability to weld pipes at various angles is crucial. The 2-Axis welding positioner facilitates welding in challenging environments, such as underwater or in remote locations, where manual positioning would be impractical or impossible.

Conclusion

The 2-Axis welding positioner is a game-changer in the world of welding equipment. Its precision engineering, dual-axis rotation and tilting capabilities, and focus on improving welding efficiency and quality make it an indispensable tool for industrial welding applications. By streamlining workflows, enhancing operator ergonomics, and ensuring consistent, high-quality welds, the Resize Machinery 2-Axis welding positioner is a key equipment for any welding operation looking to improve productivity and maintain a competitive edge.

https://www.resizeglobal.com/a-key-equipment-for-improving-welding-efficiency.html