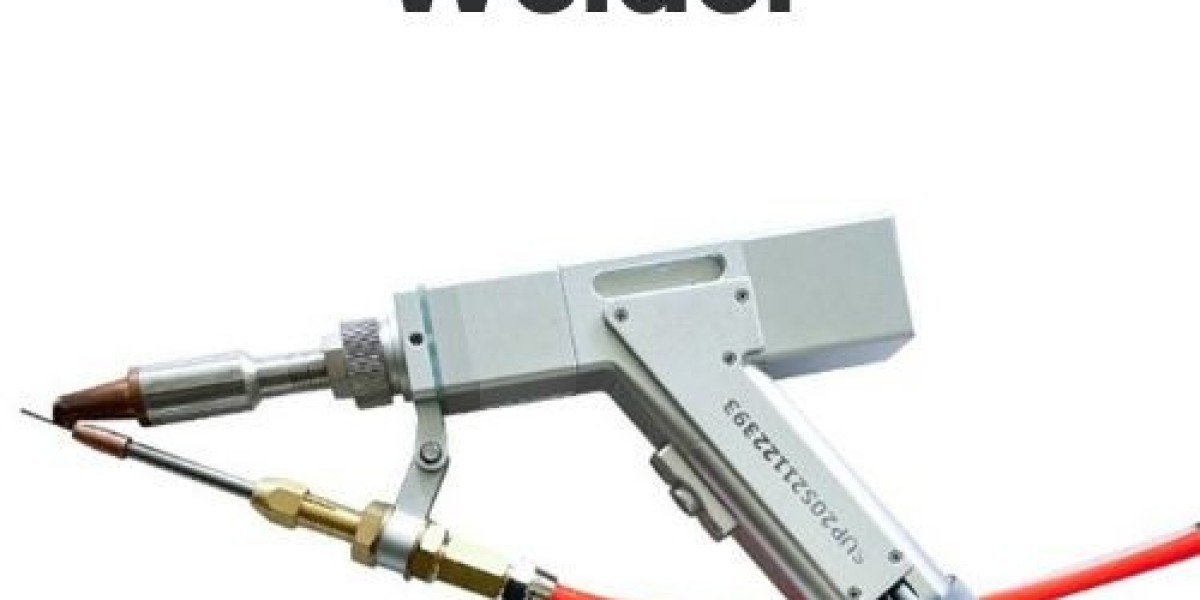

The fiber laser welder is designed to address challenges that traditional methods often struggle with, such as material distortion, slow processing speeds, and limitations in handling thin or reflective materials. The laser beam is generated within fiber optics, amplified, and then directed to the workpiece, ensuring consistent results across various applications. As industries increasingly focus on automation and precision, the fiber laser welder stands out as a versatile tool capable of meeting high standards of quality while minimizing errors.

Evolution of Fiber Laser Welding Technology

The concept of laser-based welding dates back decades, but the evolution of the fiber laser welder has been particularly significant in recent years. Early laser welding systems were bulky, less efficient, and required significant energy consumption. The integration of fiber optics revolutionized this technology by creating compact, energy-efficient, and more reliable solutions. The laser source in a fiber laser welder operates through a doped fiber, where rare-earth elements such as ytterbium amplify the laser signal. This results in a stable, high-power beam suitable for continuous use in industrial environments.

The progression from early CO2 and solid-state lasers to fiber-based systems marked a turning point for many manufacturers. The fiber laser welder introduced greater flexibility, enabling welding on complex geometries, fine edges, and delicate components without compromising structural integrity. As industries pursued precision in both mass production and specialized applications, fiber laser technology provided the necessary breakthrough.

Applications of Fiber Laser Welder in Modern Industry

One of the main reasons the fiber laser welder has gained worldwide adoption is its wide range of applications across multiple industries.

1. Automotive Industry

The automotive sector relies heavily on welding for body structures, exhaust systems, and battery components in electric vehicles. The fiber laser welder enables manufacturers to create strong, uniform welds at high speeds, supporting large-scale production while maintaining safety and durability standards.

2. Aerospace Engineering

Aircraft components require exact tolerances and structural reliability. A fiber laser welder ensures that critical parts, such as turbine blades, fuel systems, and structural frames, can be welded with minimal defects, contributing to both safety and performance in aviation.

3. Electronics Manufacturing

The trend toward miniaturization in electronics makes traditional welding methods impractical. The fiber laser welder allows precise micro-welding for sensors, batteries, and delicate circuitry without causing thermal damage to surrounding components.

4. Medical Device Production

Medical tools and implants must meet stringent hygiene and performance requirements. Fiber laser welding produces smooth, strong joints on stainless steel and titanium instruments, ensuring both safety and long-term durability in healthcare environments.

5. Energy and Power Industry

In renewable energy and power generation, the fiber laser welder plays a role in assembling solar panels, fuel cells, and other components. Its ability to work with diverse metals contributes to efficiency and innovation in energy systems.

The Process of Welding with a Fiber Laser Welder

A fiber laser welder operates by delivering a concentrated laser beam directly to the material surface, creating localized heat that melts and fuses the metals together. The process is controlled through advanced software and automation systems, ensuring repeatability and minimizing errors.

The depth and quality of the weld depend on factors such as power density, beam focus, welding speed, and material type. Operators can adjust these parameters to achieve specific results, whether working on thin sheet metals or thicker components. Unlike conventional methods, the fiber laser welder minimizes heat-affected zones, reducing material distortion and post-processing requirements.

Many systems are integrated with robotic arms and CNC platforms, allowing automated welding on complex parts. This level of integration makes the fiber laser welder an essential component of modern smart factories.

Efficiency and Reliability in Production

In industries where downtime can result in significant financial losses, reliability is a critical factor. The fiber laser welder is designed for continuous operation, with minimal maintenance compared to older technologies. Its solid-state design ensures stability, while its long operational lifespan makes it a dependable investment for manufacturers.

Efficiency is achieved through faster processing speeds and reduced need for secondary operations such as grinding or polishing. With precise welds produced on the first attempt, manufacturers save both time and material, aligning with lean manufacturing principles.

Impact on Quality Standards and Productivity

The global market increasingly demands high-quality products that can withstand rigorous testing and long-term usage. A fiber laser welder contributes to meeting these expectations by producing consistent, defect-free welds. This level of quality control enhances customer confidence and helps businesses maintain competitive advantages in highly regulated industries.

In addition to improving quality, productivity gains are significant. High welding speeds, combined with automated integration, enable manufacturers to scale production without compromising precision. The fiber laser welder has therefore become a central tool in meeting rising global demand across multiple sectors.

Future Outlook of Fiber Laser Welding

The role of the fiber laser welder is expected to grow as industries move toward advanced manufacturing practices, including Industry 4.0 and smart factories. Integration with artificial intelligence, predictive maintenance, and real-time monitoring systems will further enhance the capabilities of this technology.

Emerging materials, such as advanced alloys and composites, will require specialized welding solutions. The adaptability of the fiber laser welder positions it as a long-term solution for evolving industrial challenges. Additionally, as sustainability gains importance, the energy efficiency of fiber laser systems will align with global initiatives to reduce carbon footprints and optimize resource consumption.

Final Thoughts

The fiber laser welder represents a significant advancement in the field of welding, offering manufacturers a reliable and precise tool for modern industrial needs. From automotive to aerospace, electronics, and medical industries, its role continues to expand as businesses demand higher productivity and flawless quality. With ongoing developments in automation and smart manufacturing, the fiber laser welder is not just a current solution but a foundation for the future of industrial fabrication.