In today’s competitive manufacturing landscape, speed, consistency, and precision are critical to success. Traditional labeling processes often struggle to keep up with high-volume production and the demand for flawless results. This is where the Roll to Roll Labeling Machine steps in—offering an automated, high-performance solution for industries handling roll-based materials.

Whether it’s applying barcode labels to electronic components, printing compliance information on medical supplies, or branding fabric rolls for apparel, this technology streamlines production while ensuring label placement is perfectly aligned every time.

What is a Roll to Roll Labeling Machine?

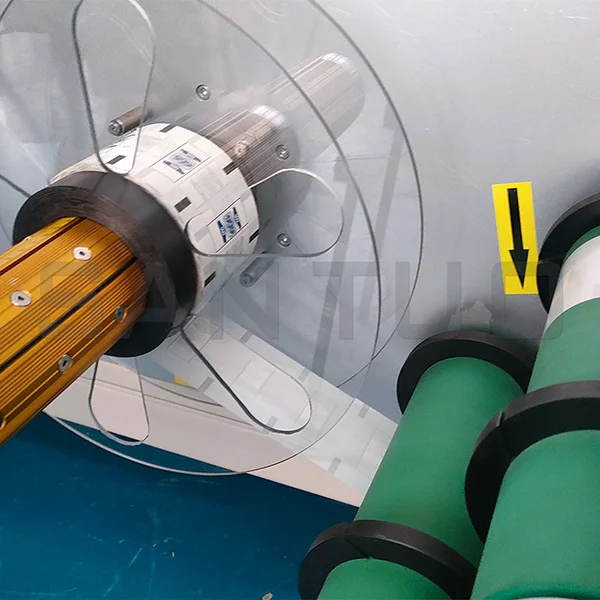

A Roll to Roll Labeling Machine is designed specifically for unwinding roll-shaped materials, applying labels to them, and rewinding them without interrupting the production process. The system ensures that labeling is done seamlessly, even at high speeds, maintaining consistent positioning and adhesion.

Key features often include:

Automatic Unwinding & Rewinding – Smooth handling of roll materials without manual intervention.

High-Precision Label Application – Advanced sensors and control systems for accurate placement.

Versatility Across Materials – Compatible with paper, films, foils, fabrics, and specialty substrates.

Customization Options – Adjustable settings for label size, placement, and material type.

Industries Using Roll to Roll Labeling Machines

Electronics

In the electronics sector, roll-to-roll labeling is essential for applying product codes, compliance markings, and safety instructions on components like circuit boards, battery packs, and cable spools. The precision of the machine ensures that even small labels are placed correctly on delicate materials.

Medical

Medical products require strict labeling compliance, including lot numbers, expiration dates, and regulatory markings. Roll-to-roll machines are ideal for labeling bandages, test strips, and sterile packaging, where precision and hygiene standards are critical.

Daily Chemicals

For household and personal care products such as cleaning wipes and cosmetic sheet masks, roll-to-roll labeling ensures brand labels are applied neatly and consistently to flexible packaging, boosting shelf appeal.

Chemical Industry

In chemical manufacturing, roll-to-roll labeling is used for safety labels on packaging materials like chemical-resistant films and liners, helping meet regulatory requirements for hazardous material handling.

Apparel

From fabric rolls to garment tags, apparel companies use roll-to-roll labeling to efficiently apply size labels, brand tags, and care instructions, ensuring consistent presentation throughout production.

Advantages of Roll to Roll Labeling Machines

High Efficiency

Capable of processing large volumes without stopping, roll-to-roll systems keep production lines moving at peak capacity.

Precision & Consistency

Advanced control systems and optical sensors guarantee that each label is placed exactly where it should be, reducing waste from misaligned labels.

Cost Reduction

Automation minimizes labor requirements and reduces errors, cutting down on wasted labels and rework.

Flexibility

The machine can be configured to handle a wide range of label sizes, shapes, and materials, making it adaptable for different product lines.

Improved Branding

Consistent, professional labeling improves brand image and ensures compliance with packaging regulations.

As industries increasingly demand higher output, greater precision, and compliance with stricter labeling regulations, the adoption of roll-to-roll labeling technology is expected to grow. Integration with digital printing, IoT monitoring, and AI-based inspection will make these machines even more versatile and intelligent.

Conclusion

The Roll to Roll Labeling Machine is more than just a piece of equipment—it’s a strategic investment for businesses in electronics, medical, daily chemicals, chemical processing, and apparel. By combining high-speed automation with precision labeling, it ensures that products meet both functional and branding requirements. In a world where efficiency and presentation are equally important, roll-to-roll labeling stands out as a transformative solution.

https://www.santuomachine.com/why-roll-to-roll-labeling-is-revolutionizing-product-packaging.html