Introduction

Polyurethane hot melt adhesives (PU HMAs) have become a pivotal element in the modern adhesive market due to their unique combination of performance, flexibility, and environmental advantages. Unlike traditional solvent-based adhesives, PU HMAs are applied in a molten state and solidify upon cooling, creating a strong bond that is both durable and elastic. This distinctive characteristic has driven widespread adoption across a multitude of industries, from packaging and automotive to footwear and electronics.

Market Overview

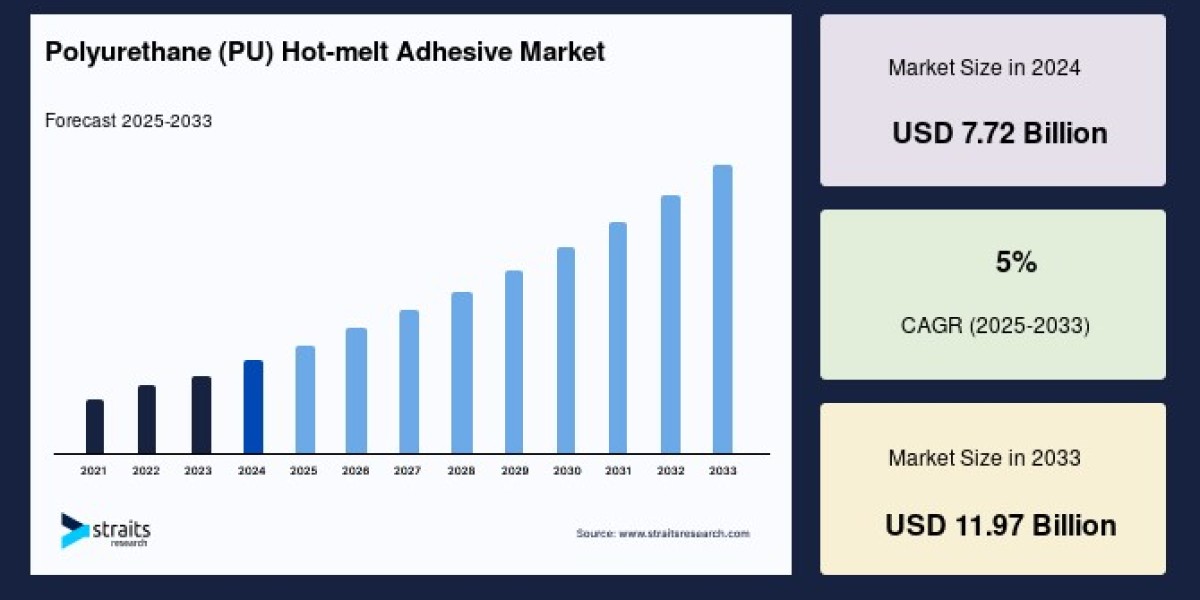

The global polyurethane (pu) hot-melt adhesive market size was valued at USD 7.72 billion in 2024 and is projected to reach from USD 8.10 billion in 2025 to USD 11.97 billion by 2033, growing at a CAGR of 5% during the forecast period (2025-2033).

The global demand for PU hot melt adhesives has witnessed steady growth in recent years, driven by industrial expansion, technological advancements, and increasing environmental regulations that favor low-emission adhesive solutions. The market is expected to continue expanding significantly over the coming decade, supported by rising industrial activities, urbanization, and innovation in adhesive technologies.

Key Applications

PU hot melt adhesives serve critical roles in various sectors, including:

Packaging Industry: These adhesives are widely used for carton sealing, consumer goods packaging, and protective packaging applications. Their fast-setting properties and strong bonding capabilities make them ideal for high-speed packaging lines.

Automotive Industry: In automotive manufacturing, PU HMAs are essential for bonding interior trim, headliners, door panels, and other components, offering flexibility and resistance to vibrations and temperature variations.

Footwear Manufacturing: PU HMAs provide durable and flexible bonds for different shoe components, contributing to comfort and longevity of the footwear.

Textile and Apparel: The adhesives enable fabric bonding without damaging delicate textiles, improving garment manufacturing efficiency.

Electronics Assembly: In electronics, these adhesives are used to bond components securely while withstanding heat and mechanical stress.

Furniture and Woodworking: PU HMAs provide strong adhesion for wood panels and laminates, aiding in furniture production with enhanced durability.

Healthcare and Medical Devices: Adhesives are used in medical device assembly where biocompatibility and reliability are crucial.

Bookbinding: The adhesive’s flexibility and strong hold make it suitable for binding books and publications.

Market Drivers

Several factors contribute to the growing demand for polyurethane hot melt adhesives:

Environmental Benefits: PU HMAs offer a solvent-free alternative, reducing volatile organic compound (VOC) emissions and aligning with global sustainability goals.

Technological Innovation: Advances in formulation chemistry have enhanced the adhesive performance, allowing for better bonding on diverse substrates, faster curing times, and improved heat resistance.

Growth in End-Use Industries: Rapid industrialization in emerging markets, expanding automotive production, and increasing e-commerce packaging requirements are major growth catalysts.

Customization and Flexibility: PU HMAs can be tailored to specific applications, including variations in viscosity, open time, and curing profiles, enabling manufacturers to meet diverse industrial needs.

Regional Dynamics

The market shows regional diversity in growth and adoption:

Asia-Pacific: This region dominates due to rapid industrial growth, expanding manufacturing sectors, and increased demand from automotive and packaging industries. Developing economies are investing heavily in infrastructure, boosting the consumption of PU HMAs.

Europe: Europe is expected to witness significant growth due to stringent environmental regulations and a strong focus on sustainable manufacturing practices. Innovation in adhesive technologies and adoption of eco-friendly materials are key trends.

North America: The mature market in North America emphasizes technological integration and quality standards, supporting steady demand in automotive, packaging, and healthcare sectors.

Rest of the World: Emerging markets in Latin America, the Middle East, and Africa are gradually increasing their adoption, driven by infrastructural development and industrial expansion.

Challenges

Despite its strong market prospects, the polyurethane hot melt adhesive sector faces several challenges:

Raw Material Price Volatility: Fluctuating costs of raw materials such as polyols and isocyanates impact production expenses and pricing strategies.

Regulatory Compliance: Meeting diverse environmental and safety regulations across regions requires continuous innovation and compliance management.

Competition from Alternative Adhesives: Other adhesive technologies, including water-based and reactive adhesives, pose competitive pressure, requiring continuous improvement of PU HMA formulations.

Technological Trends and Innovations

Technological progress is shaping the future landscape of PU hot melt adhesives:

Bio-Based and Sustainable Adhesives: Development of bio-based raw materials and recyclable adhesive systems addresses growing demand for environmentally responsible products.

Enhanced Formulations: Innovations focusing on improved adhesion strength, heat resistance, and elasticity are expanding application possibilities.

Automation and Smart Manufacturing: Integration of Industry 4.0 technologies such as real-time monitoring, process automation, and predictive maintenance optimizes adhesive application efficiency and quality.

Future Outlook

The polyurethane hot melt adhesive market is expected to experience sustained growth with a focus on sustainability, technological advancements, and expanding industrial applications. Companies investing in research and development to create high-performance, eco-friendly adhesives will have a competitive edge. The rise in e-commerce, automotive production, and infrastructure projects worldwide will continue to fuel demand.

Furthermore, collaborative innovation among adhesive manufacturers, raw material suppliers, and end-users will drive the creation of tailored solutions that meet evolving market needs and regulatory requirements.

Conclusion

Polyurethane hot melt adhesives represent a versatile and increasingly preferred bonding solution across multiple industries. Their unique properties, environmental benefits, and adaptability position them well for future market growth. As industries worldwide focus on sustainability, efficiency, and innovation, PU HMAs will play a vital role in meeting these objectives, contributing significantly to the evolving adhesive landscape.