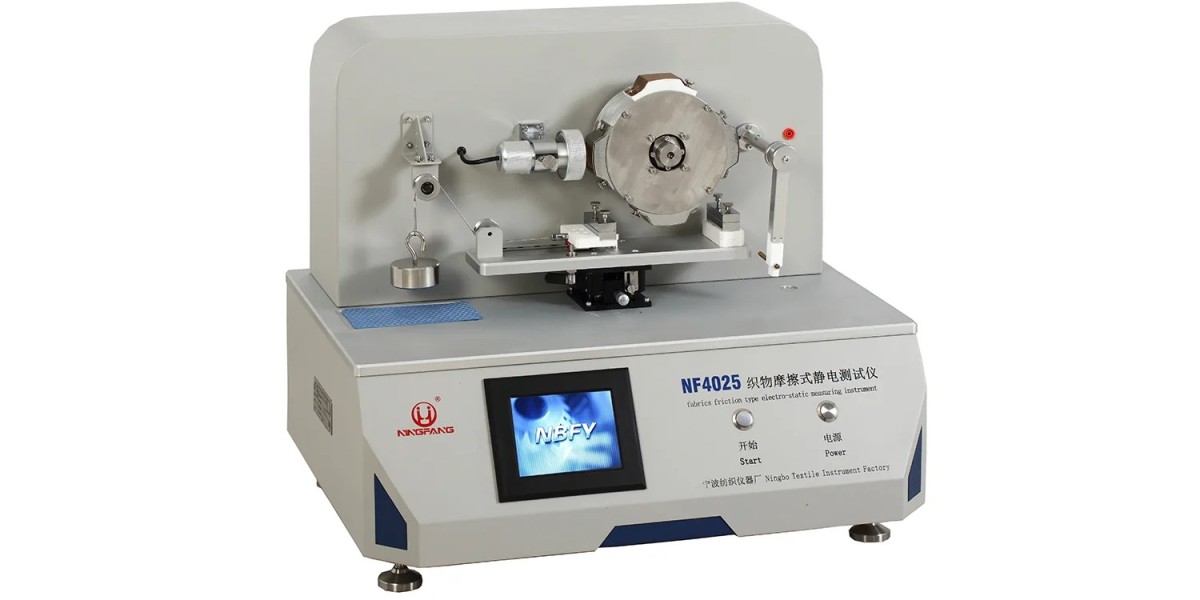

In the textile industry, understanding and controlling the static properties of fabrics is crucial for ensuring product quality, enhancing wearer comfort, and complying with safety standards. Static electricity, generated through friction or contact, can cause a myriad of issues ranging from fabric pilling to shocking sensations and even dust attraction, compromising the overall performance and appeal of textiles. To address these challenges, Ningbo Textile Instrument Factory proudly introduces the NF4025 fabric friction electrostatic tester – a cutting-edge solution for accurately measuring and analyzing the static properties of textiles.

NF4025 Fabric Friction Electrostatic Tester: A Precision Tool for Static Evaluation

Advanced Touch Screen Control for Seamless Operation

At the heart of the NF4025 lies its intuitive touch screen interface, a defining feature that sets it apart from conventional testing instruments. Touch Screen Control not only simplifies the testing process but also elevates user experience, allowing operators to navigate through menus, adjust settings, and monitor test progress with ease. This modern design eliminates the need for complex buttons and dials, ensuring that even novice users can perform accurate tests with minimal training.

Automated Motor Stop for Enhanced Safety and Efficiency

Efficiency and safety are paramount in industrial settings, and the NF4025 excels in both aspects. The tester is equipped with an Automatic Motor Stop feature that seamlessly halts the friction process once the pre-set time expires. This not only ensures that tests are conducted with precise timing but also prevents potential damage to the fabric sample or the instrument itself, safeguarding against overheating or excessive wear. By automating this critical step, the NF4025 guarantees consistent and reliable results while minimizing operator intervention.

Automated Detection of Friction Electrification Voltage

At the core of its functionality, the NF4025 excels in its ability to Automatically Detect Friction Electrification Voltage. This sophisticated feature enables the tester to measure the electrostatic charge generated during the friction process, providing crucial insights into the fabric's static properties. By continuously monitoring and recording these data points, the NF4025 delivers highly accurate and repeatable results, helping manufacturers optimize fabric design and production processes to minimize static-related issues.

Simple and Fast Operation for Maximized Productivity

In today's fast-paced textile industry, time is money. The NF4025 fabric friction electrostatic tester recognizes this and is designed for Simple and Fast Operation. Its streamlined workflow, combined with user-friendly software, ensures that tests can be set up and executed quickly, without compromising on accuracy. This translates into increased productivity and reduced downtime, allowing manufacturers to stay ahead of the competition.

Conclusion

The NF4025 fabric friction electrostatic tester from Ningbo Textile Instrument Factory represents a significant advancement in textile testing technology. With its advanced touch screen control, automated features, and focus on simplicity and speed, this instrument is the ideal solution for textile manufacturers and researchers seeking to accurately measure and analyze the static properties of their fabrics. By investing in the NF4025, businesses can enhance product quality, improve wearer comfort, and maintain compliance with industry standards, ultimately driving success in today's demanding market.

https://www.nbfyti.com/accurately-measure-the-static-properties-of-textiles.html