Proper Z height calibration is one of the most critical steps in ensuring successful 3D printing. Incorrect Z height can result in poor adhesion, uneven first layers, and failed prints. For PrusaSlicer users, understanding and mastering Z height calibration can significantly enhance print quality and consistency. This guide will explore essential techniques and strategies to optimize your Z height calibration for PrusaSlicer.

Z height calibration for PrusaSlicer ensures that your nozzle is set at the correct distance from the print bed. Too close, and the filament may not extrude smoothly, potentially damaging your print surface. Too far, and the filament won’t adhere, causing warping or layer separation. Achieving the perfect Z height is crucial for both FDM printing efficiency and the overall longevity of your printer components.

Understanding Z Height Calibration Basics

Before diving into advanced techniques, it is essential to grasp the fundamentals of Z height calibration for PrusaSlicer. Z height refers to the distance between the printer nozzle and the print bed at the start of the printing process. Correctly calibrated Z height allows the first layer of filament to adhere firmly to the bed while maintaining a uniform extrusion pattern.

Z height calibration for PrusaSlicer is closely tied to the bed leveling process. A misaligned bed can make even the most precise Z height ineffective, leading to uneven first layers. By understanding the interplay between bed leveling and Z height, users can prevent common printing issues such as under-extrusion, gaps, and filament dragging. Getting these fundamentals right sets the stage for all subsequent calibration adjustments.

Manual Z Height Calibration Techniques

Manual Z height calibration remains a popular method due to its simplicity and effectiveness. Start by using a piece of standard printer paper to measure the distance between the nozzle and the print bed. Adjust the Z height until the paper slides under the nozzle with slight resistance, ensuring that the filament will have adequate contact without being overly compressed.

Another essential manual technique involves observing the first layer during printing. Watch for signs of filament squishing too much or not sticking at all. Slight adjustments to the Z height in real-time can correct minor issues that paper testing might not detect. Manual Z height calibration for PrusaSlicer gives users direct control and immediate feedback, which is particularly beneficial for troubleshooting tricky prints.

Leveraging PrusaSlicer’s Calibration Features

PrusaSlicer offers built-in features that simplify Z height calibration, making it more precise and less time-consuming. The first step is to utilize the calibration wizard or Z calibration routine provided within the software. This tool helps users fine-tune the nozzle distance based on their printer model and filament type, offering step-by-step guidance for optimal first layer adhesion.

Additionally, PrusaSlicer allows users to adjust Z offset settings in the slicer interface. This adjustment enables fine-tuning of the nozzle height without physically altering the bed or hardware. By combining the software’s calibration tools with careful observation of first-layer quality, users can achieve consistent results with minimal trial and error. Z height calibration for PrusaSlicer through its native tools is a reliable approach for both beginners and experienced printers.

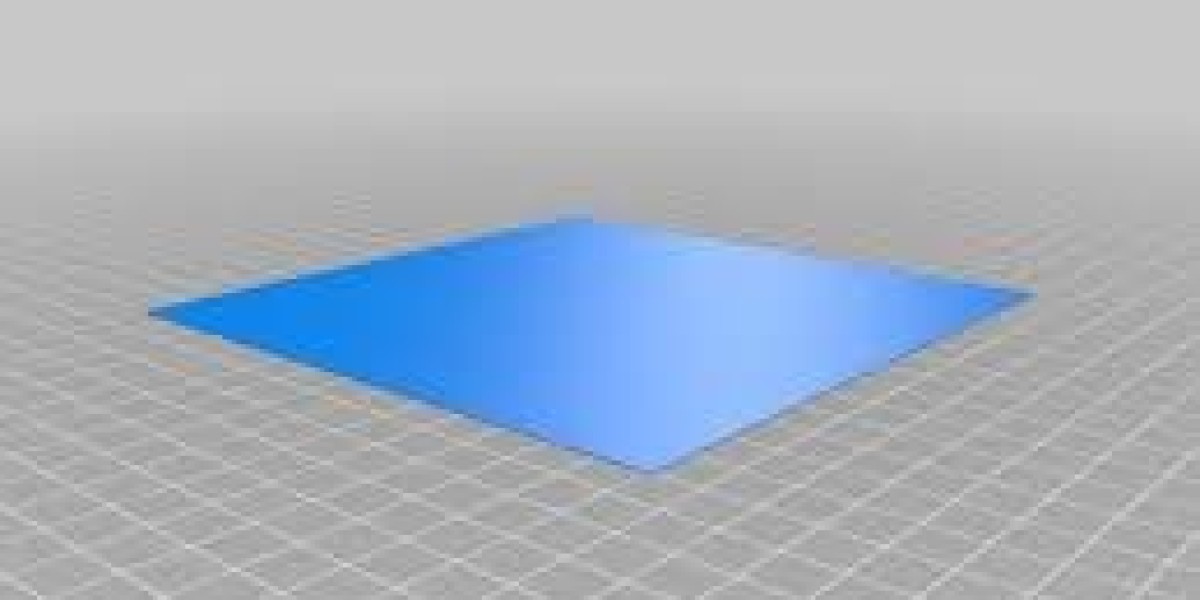

Using Test Prints for Precise Z Height Adjustment

One of the most effective ways to perfect Z height calibration for PrusaSlicer is through dedicated test prints. Common test prints include single-layer squares, calibration cubes, and first-layer calibration patterns. These prints provide immediate visual feedback on how well the filament adheres and whether the nozzle height needs further adjustment.

When performing test prints, pay attention to the filament’s width and the appearance of the lines. Lines that are too thin or not sticking indicate the nozzle is too high, while overly squished lines indicate it is too low. Iteratively adjusting the Z height based on these test prints allows for precise control over the first layer, ultimately improving print success rates and surface quality. Regular use of test prints is an indispensable technique for achieving optimal Z height calibration for PrusaSlicer.

Advanced Tips for Consistent Z Height

Beyond basic and software-assisted calibration, advanced users can adopt techniques that ensure long-term Z height consistency. One such method is temperature-based calibration, which accounts for filament expansion and contraction during printing. Adjusting the Z height slightly based on the operating temperature can prevent first-layer issues caused by thermal variances.

Another advanced approach involves periodic recalibration of the printer’s mechanical components. Even minor changes in bed tension, nozzle wear, or frame stability can affect Z height accuracy. By combining mechanical maintenance with precise Z offset settings in PrusaSlicer, users can maintain consistent first-layer quality across multiple prints. Implementing these advanced strategies ensures that Z height calibration for PrusaSlicer remains accurate, reducing print failures and enhancing overall reliability.

Conclusion

Mastering Z height calibration for PrusaSlicer is a critical skill for any 3D printing enthusiast. From understanding basic principles to utilizing software tools, manual adjustments, test prints, and advanced techniques, each step contributes to achieving perfect first layers. Proper Z height calibration not only improves print quality but also extends the life of your printer and reduces material waste. By implementing these strategies consistently, users can maximize the potential of their Prusa printers and enjoy smoother, more reliable printing experiences.