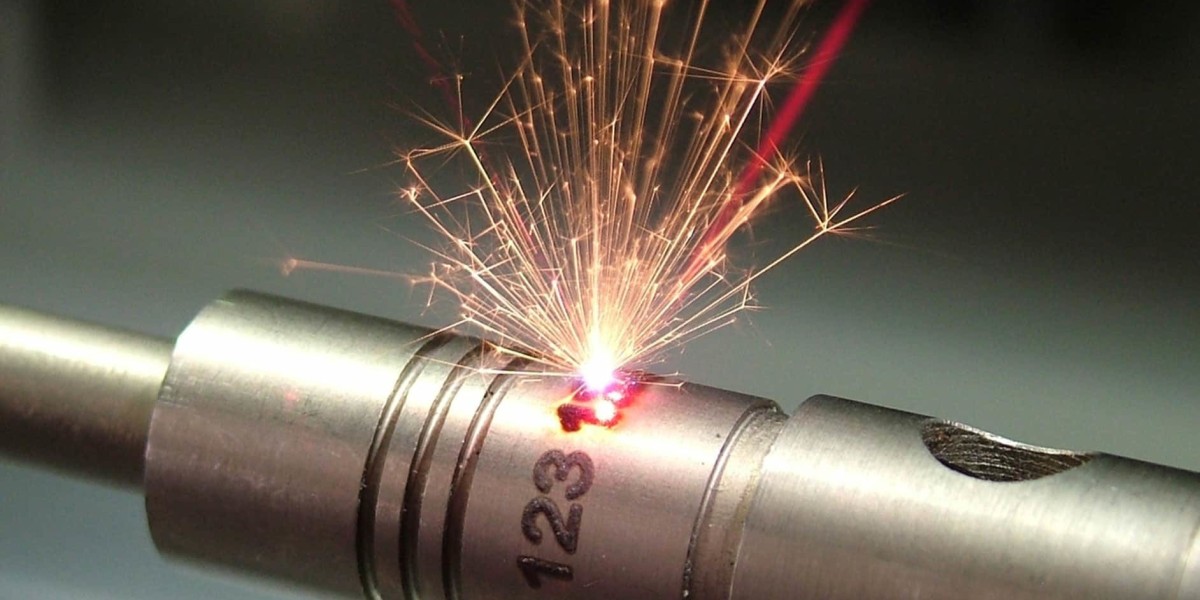

Laser marking is a non-contact, high-precision technique that uses a focused laser beam to alter the surface of a material for identification or design purposes. This process is widely used across industries for engraving serial numbers, barcodes, logos, and other permanent identifiers on metals, plastics, ceramics, and glass.

Why Mart Laser Stands Out in Laser Marking Solutions

Mart Laser has established itself as a reliable and forward-thinking manufacturer of industrial laser equipment. With years of experience in laser machinery design, engineering, and technical support, the company has built a reputation for delivering robust, efficient, and cost-effective laser marking systems tailored for various industries.

Key Features of Mart Laser’s Laser Marking Machines:

| Feature | Description |

|---|---|

| Precision | Ultra-fine laser beams with micron-level marking accuracy |

| Speed | High-speed galvanometer scanners reduce production time |

| Versatility | Works with metals, plastics, glass, ceramics, and coated materials |

| Automation Options | Integrates with robotic arms and conveyors for industrial automation |

| Low Maintenance | Air-cooled, sealed laser sources with long service life |

| Eco-Friendly | No inks, chemicals, or consumables required |

Types of Laser Marking Machines at Mart Laser

Fiber Laser Marking Machines

Ideal for marking on metal surfaces and high-density plastics. Offers deeper engraving and longer-lasting marks.CO₂ Laser Marking Machines

Suitable for non-metal materials such as wood, leather, paper, and acrylic. Frequently used in packaging and textile industries.UV Laser Marking Machines

Delivers cold marking for heat-sensitive materials like medical plastics and glass.

Applications of Mart Laser Marking Technology

Industrial Use Cases:

Automotive Parts

VIN numbers, brake system codes, gear specificationsElectronics & PCB

Circuit IDs, component branding, micro-markingMedical Devices

Stainless steel surgical tools, plastic syringes, UDI codesAerospace Components

Turbine blades, fasteners, heat-resistant labelsJewelry and Watches

Custom engraving, serial numbers, brand logos

Product Personalization:

Customized giftware

Luxury branding

QR codes for product traceability

Why Laser Marking is the Industry Standard Today

Bullet Point Insights:

Non-contact process ensures no physical wear or deformation

Environmentally responsible – no inks, solvents, or emissions

Highly legible and durable even under harsh conditions

Supports traceability, a critical requirement for regulatory compliance

Integration-ready for Industry 4.0 environments

FAQs About Laser Marking at Mart Laser

Q1: How long does a laser mark last?

A laser mark is permanent and resistant to fading, corrosion, and wear. Under normal conditions, it can last for the lifetime of the part.

Q2: Can laser marking damage heat-sensitive materials?

Mart Laser offers UV laser machines specifically designed for low-thermal impact marking, ideal for plastics and electronics.

Q3: Is laser marking safe to use in small workshops?

Yes, Mart Laser provides enclosed models that include proper ventilation and shielding for compact and safe usage.

Q4: What industries benefit most from Mart Laser machines?

Industries such as automotive, electronics, aerospace, medical, packaging, and consumer goods benefit immensely from Mart Laser's systems.

Q5: Does Mart Laser provide training and support?

Yes, Mart Laser provides comprehensive user manuals, virtual training sessions, and technical support for all its machines.

Final Thought

As manufacturers face growing demands for product traceability, speed, and quality, Mart Laser continues to deliver advanced laser marking systems that align with these industrial needs. Whether you’re running a high-volume factory or a custom job shop, Mart Laser’s solutions combine performance, precision, and reliability.